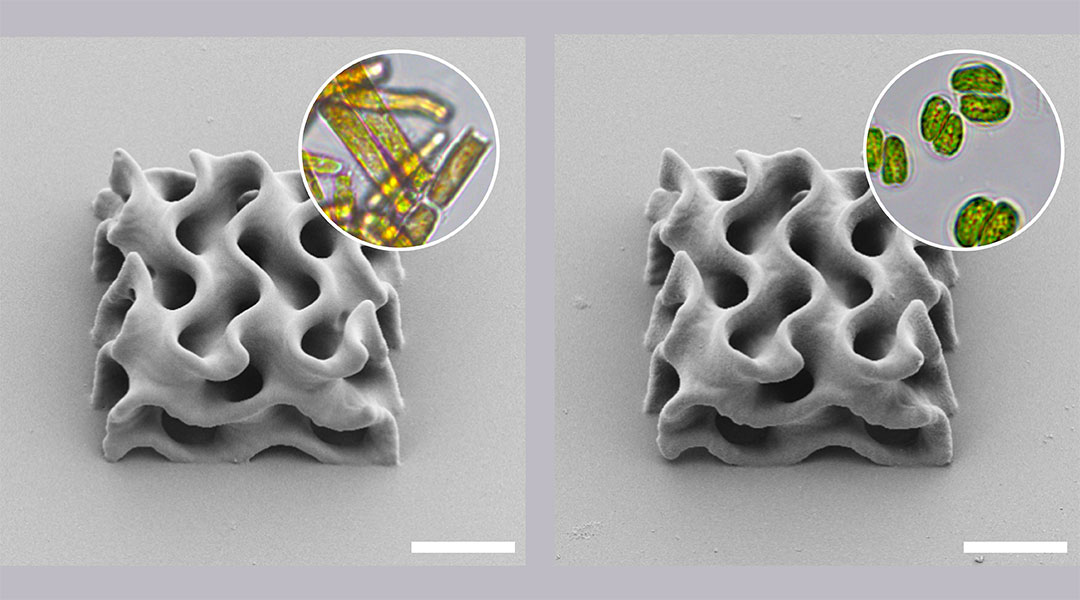

A search for environmentally friendly inks led researchers to microalgae biofactories, providing a renewable biomass solution.

A search for environmentally friendly inks led researchers to microalgae biofactories, providing a renewable biomass solution.

Plant cells outperform yeast or bacteria in producing spider silk proteins, enhancing production efficiency.

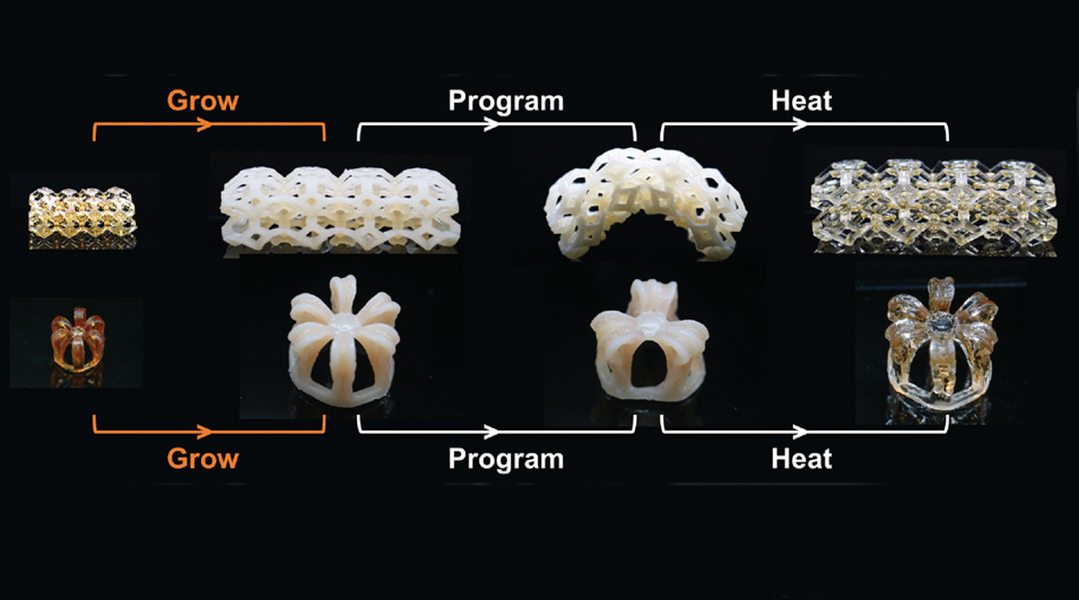

Taking inspiration from nature, scientists create a two-component catapult that overcomes limitations in 4D printing.

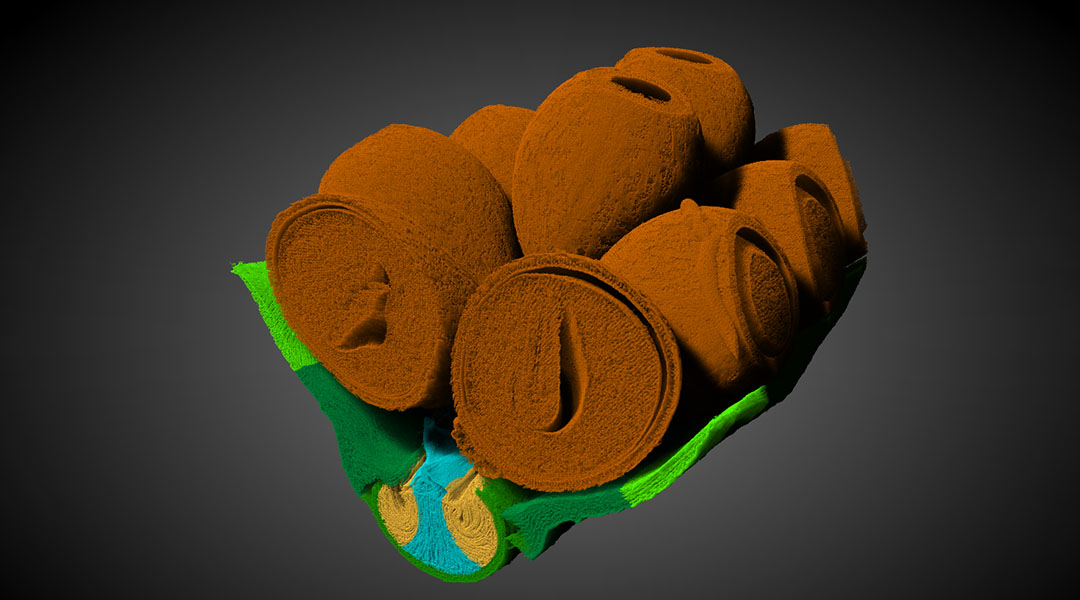

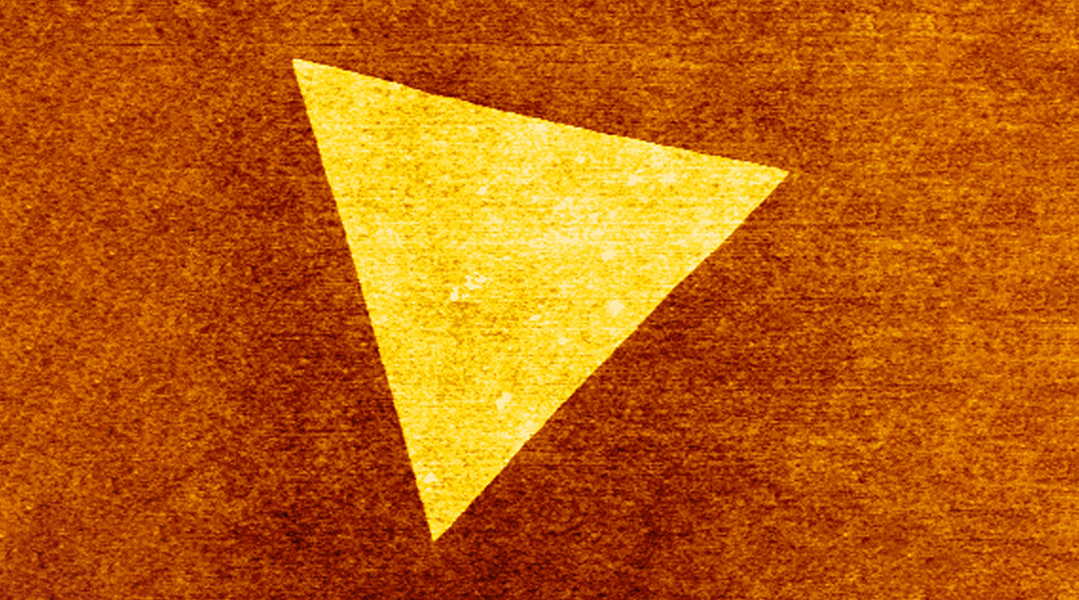

Using the adhesive properties of ice, researchers have developed a transfer method to move large sheets of 2D materials without breaking them.

4D printing produces a living polymer network that can be printed into 3D shapes and then broken down into its monomer units for reuse.

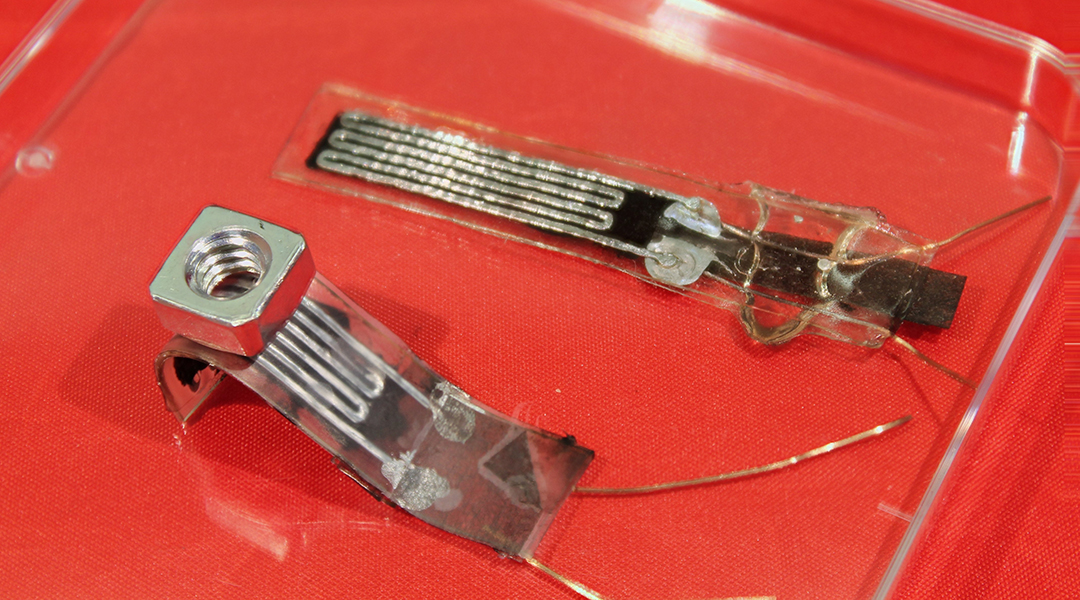

4D printing of metallic shape-morphing systems can be applied in many fields, including aerospace, smart manufacturing, naval equipment, and biomedical engineering.

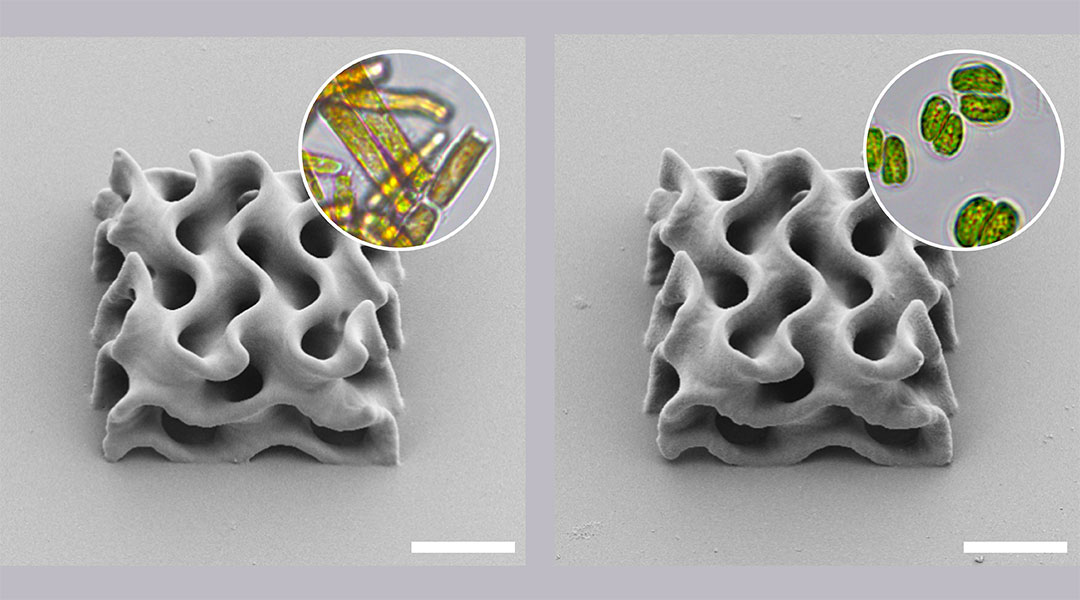

Blood coagulation is a common but delicate physiological behavior and is inspiring new porous materials.

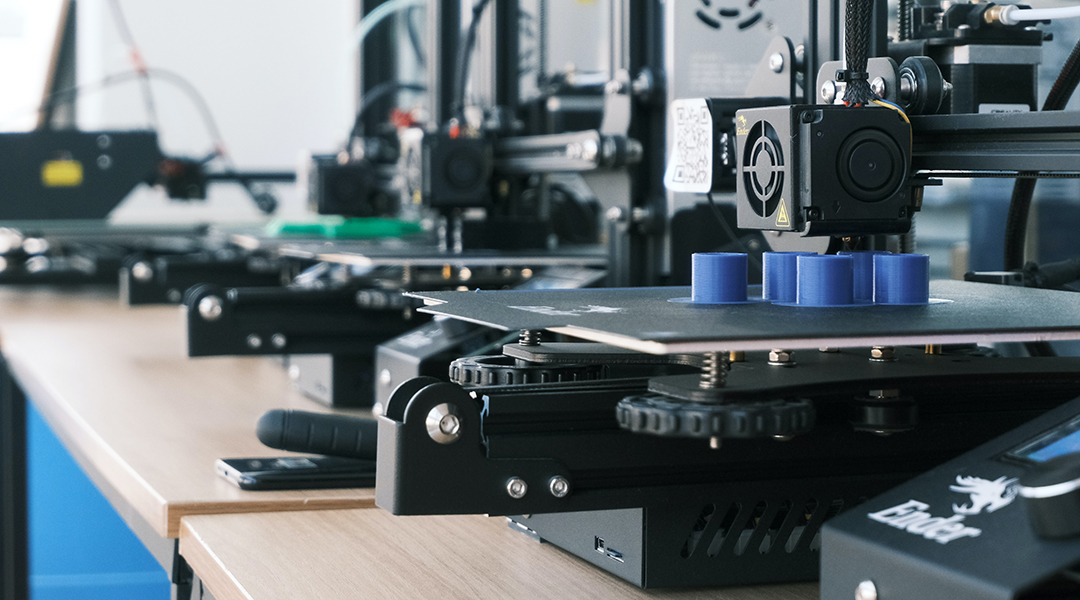

To optimize 3D printing, researchers apply machine learning to minimize waste and optimize structure during the printing process.

A new surface treatment enhances the adhesion of double-sided tape to make stickier tapes for soft electronics.

Using light-based polymerization, researchers have reduced the amount of time needed to 3D print certain medicines from minutes to seconds.