“Free of conductive additives, binders, commercial separators, and current collectors.” This claim, from researchers at Tsinghua University, China, reads like the health claims on my box of afternoon cereal. More seriously, it reads like the recipe for a highly simplified, low cost energy storage device, which they have produced using a TiO2-assisted UV reduction of sandwiched graphene components.

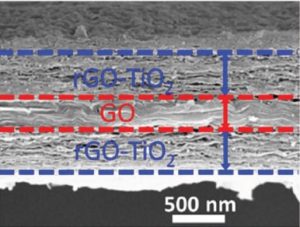

The sandwich structure consists of two active layers of reduced graphene oxide hybridised with TiO2, with a graphene oxide separator (rGO-TiO2/rGO/rGO-TiO2). In the completed device, the separator layer also acts as a reservoir for the electrolyte, which affects ion diffusion—a known problem for layered membrane devices—and affects both the capacity and rate performance.

The sandwich structure consists of two active layers of reduced graphene oxide hybridised with TiO2, with a graphene oxide separator (rGO-TiO2/rGO/rGO-TiO2). In the completed device, the separator layer also acts as a reservoir for the electrolyte, which affects ion diffusion—a known problem for layered membrane devices—and affects both the capacity and rate performance.

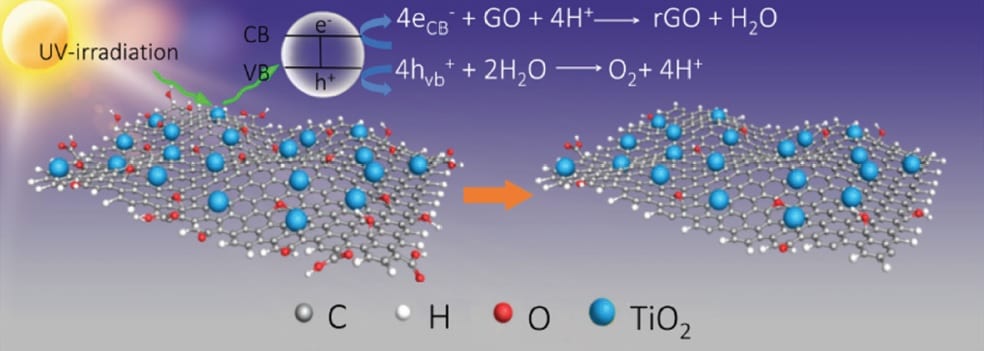

A step-by-step vacuum filtration process is used to form the membrane structure, and the amount of graphene oxide used in the filtration solutions can be adjusted to precisely tune t he thickness of each layer. Irradiation of the dried membrane with UV light then reduces the graphene oxide to rGO with assistance from the TiO2.

The electrochemical performance of the hybrid active layer was clearly affected by the reduction time, with anything less than 40 minutes being too short to completely reduce the graphene oxide, leading to lower electrical conductivity and, therefore, reduced capacitance of the membrane. Going beyond 40 minutes of UV irradiation, suggest the researchers, strips the functional groups from the rGO surface, leading to a lower pseudocapacitance.

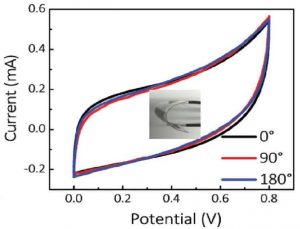

The membrane supercapacitor also demonstrated good mechanical stability, with an essentially unchanged electrochemical performance when tested at bending angles of 90 and 180 degrees.

The method used by these researchers to generate compact, thin-film, energy storage structures offers good control over the synthetic parameters while being very easy and user-friendly, and is not limited to the production of supercapacitors.

Check out the rest of the experimental details in Advanced Materials Interfaces.