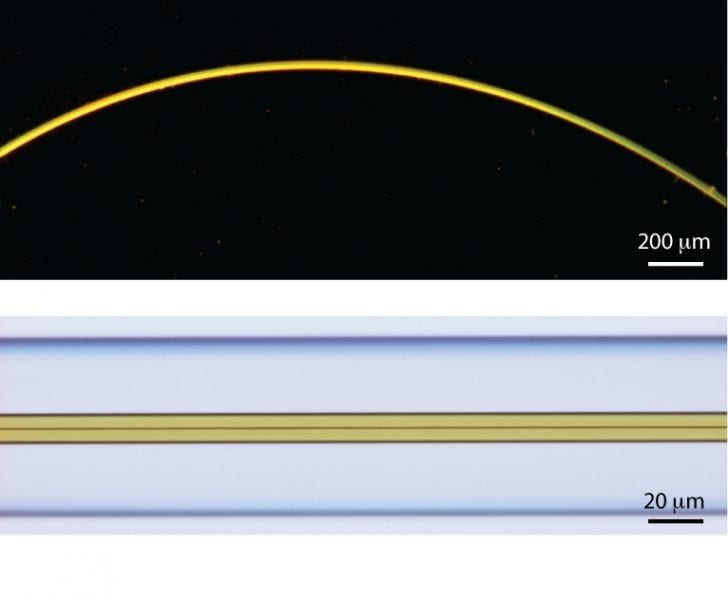

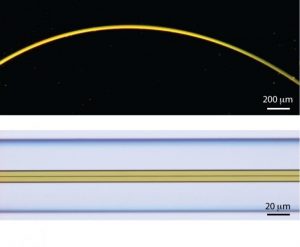

High-performance optoelectronic devices are usually made from compound semiconductors because these materials have good light emission efficiency and electronic properties. Until now, semiconductor fibers for such devices were made by depositing only unary semiconductors into silica pores. Such fibers have semiconductor characteristics and also retain the features of the silica pores, including robustness and compatibility with existing optical fiber technology. A team of researchers has paved the way for the development of new devices with their report of the production of compound semiconductor optical fiber waveguides. The first fibers were made by depositing ZnSe into silica pores using high-pressure chemical vapor deposition. This exciting new type of optical fiber will help build next-generation devices, such as fiber lasers with higher output powers and better beam profiles than those available today.

High-performance optoelectronic devices are usually made from compound semiconductors because these materials have good light emission efficiency and electronic properties. Until now, semiconductor fibers for such devices were made by depositing only unary semiconductors into silica pores. Such fibers have semiconductor characteristics and also retain the features of the silica pores, including robustness and compatibility with existing optical fiber technology. A team of researchers has paved the way for the development of new devices with their report of the production of compound semiconductor optical fiber waveguides. The first fibers were made by depositing ZnSe into silica pores using high-pressure chemical vapor deposition. This exciting new type of optical fiber will help build next-generation devices, such as fiber lasers with higher output powers and better beam profiles than those available today.

ZnSe is attractive for use in fiber lasers because it has excellent optical transmission over a wide wavelength range spanning from the visible to IR and is also an efficient gain medium. Additionally, such compound semiconductors have large optical nonlinearities that are important for frequency conversion, i.e., changing the color of light. To synthesize the ZnSe optical fibers, researchers chose suitable precursors compounds that optimized the deposition in the silica pores and avoided pre-reactions. The morphology and composition of the deposited material could be tuned by adjusting the precursor ratio. Using high-pressure chemical vapor deposition allows for high production rates, particularly if multiple fibers are fabricated simultaneously, and flexibility in the geometrical design of the final structure. Spectroscopic studies confirmed the purity of the fiber waveguides and the electronic properties were similar to those of optical grade ZnSe standards. Future work will be toward minimizing (and possible eliminating) the void at the center of the fiber, which will improve beam quality and allow for application of the fibers in an even broader range of new devices.