Breathable and waterproof membranes (Gore-Tex, Sympatex, etc.,) are best known for their use in rain-proof apparel, but also find applications in medical devices, for moisture regulation of buildings, in water desalination or in waste water purification. A major drawback of these membranes is that they are easily damaged and then become leaky.

Breathable and waterproof membranes (Gore-Tex, Sympatex, etc.,) are best known for their use in rain-proof apparel, but also find applications in medical devices, for moisture regulation of buildings, in water desalination or in waste water purification. A major drawback of these membranes is that they are easily damaged and then become leaky.

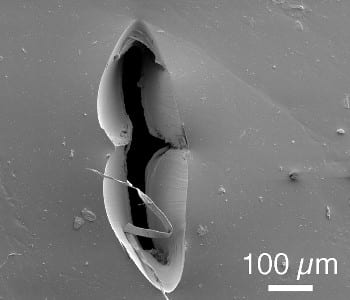

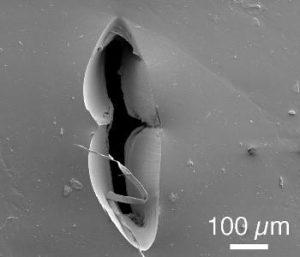

Bruns and co-workers, in an attempt to develop a better material, have produced a composite membrane that remains water-tight even if punctured with a sharp item. It is based on a thin breathable membrane onto which an amphiphilic polymer conetwork (APCN) was synthesized. APCNs are water-swellable, rubbery materials. Punctures in the two-layered composite membrane are sealed by this layer, so that the damaged membranes can withstand water pressures of at least 1.6 bar. The additional layer does not interfere with evaporation of liquid water through the membrane, which makes the material suitable, e.g., for medical cooling devices that alleviate symptoms of multiple sclerosis.