Protective coatings safeguard the underlying substrate material from environmental attack and are critical for operating in harsh conditions. When the coating is damaged this protective function is eliminated, and the substrate becomes exposed to undesirable environmental conditions. Self-healing materials have been developed for the autonomous repair of damage in coatings. Though significant advancements have been made, the realizations of self-healing technology remain elementary compared to natural systems.

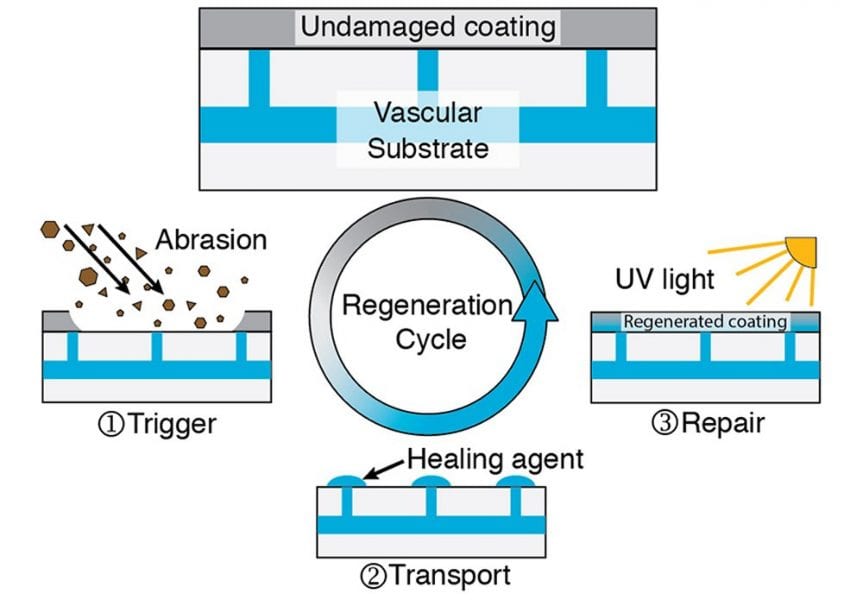

Many self-healing coatings that exist to date are limited to small-scale damage, can only repair one damage cycle, and heal with material different than the native coating. In their recent work published in Advanced Engineering Materials, Prof. Scott White’s group from the University of Illinois at Urbana-Champaign demonstrates a regenerative coating system inspired by biology that is a simplified synthetic analog of skin, with a vascularized substrate (dermis-like) and protective coating (epidermis-like).

The protective polymeric coating is regenerated in response to complete removal of the coating by abrasive damage. Abrasion exposes the underlying vasculature, and UV curable fluid is delivered to the site of damage via a pressure responsive surface valve. The valve isolates unreleased healing fluid from sunlight, preventing contamination and blockage of the vasculature. The UV curable fluid solidifies and reforms the protective coating when exposed to simulated sunlight. The valve and vascular substrate system facilitate the recovery from repeat damage events, restoring the coating with properties identical to the native material.

The demonstrated regenerative coating system has the potential to extend the service life of engineered coatings, and the pressure sensitive valves could be integrated with additional components such as pumps and reservoirs and extended to preform additional functions.