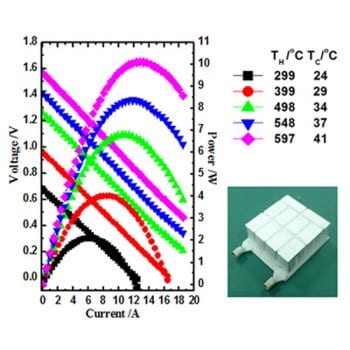

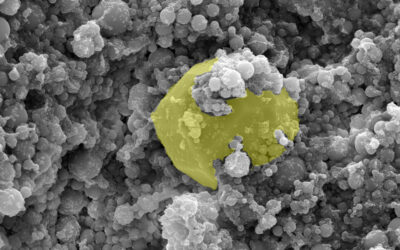

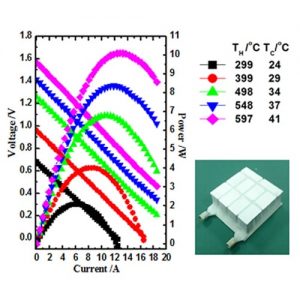

Thermoelectric (TE) devices have been identified as promosing converters for energy harvesting due to their capability to directly convert heat into electricity. They have the advantages of solid-state operation, no mechanical moving parts, no release of greenhouse gases, good stability and high reliability, which have been utilized or are at the trial stage in fields such as military, aerospace, transportation, medical services, electronics, and so on. Recent researches and developments of high-temperature TE materials, such as skutterudites, half-Heusler alloys, and so on, have demonstrated great potential for the recovery of vehicle exhaust heat. Thermoelectrics based on classic bismuth telluride have also started to impact the automotive industry by enhancing air-conditioning efficiency and integrating cabin climate control. The engineering challenge of making reliable and efficient devices is to make them withstand thermal and mechanical cycling.

Thermoelectric (TE) devices have been identified as promosing converters for energy harvesting due to their capability to directly convert heat into electricity. They have the advantages of solid-state operation, no mechanical moving parts, no release of greenhouse gases, good stability and high reliability, which have been utilized or are at the trial stage in fields such as military, aerospace, transportation, medical services, electronics, and so on. Recent researches and developments of high-temperature TE materials, such as skutterudites, half-Heusler alloys, and so on, have demonstrated great potential for the recovery of vehicle exhaust heat. Thermoelectrics based on classic bismuth telluride have also started to impact the automotive industry by enhancing air-conditioning efficiency and integrating cabin climate control. The engineering challenge of making reliable and efficient devices is to make them withstand thermal and mechanical cycling.

Researchers from Shanghai Institute of Ceramics, CAS in China and University of Michigan in USA give a comprehensive review on recent progress of the bismuth telluride-based and the skutterudite-based TE devices. The bottlenecks of these TE generation devices before industrial application, including the mass production of TE materials, the design and fabrication of high performance TE devices, the performance evaluation method and service behavior of the TE devices, have been pointed out. The authors also present the challenges and the potential development trends for the research of TE power generation devices in the future.