Recent years have seen a rise in 3D printing technologies and researchers are increasingly interested in printable electronic materials.

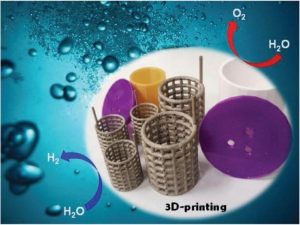

In Advanced Functional Materials, Dr. Adriano Ambrosi and Professor Martin Pumera from Nanyang Technological University demonstrate a set-up for 3D printing electrodes followed by electrochemical surface modification that could be used to create a vast variety of tailorable electronic devices. Specifically, in their research they use 3D metal and polymer printing to create a self-contained electrochemical system (electrochemical cell and electrodes) for water splitting applications. This combined approach allows for optimization of both electrode design and dimensions, and the catalytic material to be used.

They use selective laser melting to manufacture gauze-shaped, stainless-steel electrodes that are then surface-modified by electrodeposition to tune their electrocatalytic properties toward hydrogen and oxygen evolution. They then tested the best performing electrodes (those surface-modified with catalytic IrO2 and Pt) in a fully 3D-printed proof-of-concept water electrolyzer, which they powered using a commercially available alkaline battery, demonstrating its effective water-splitting ability.

Importantly, the electrodeposition can be controlled so that only the required amount of catalytic material is used, reducing waste in the fabrication process.