3D printing has revolutionized the manufacturing of complex shapes in the last few years. Using additive depositing of materials, where individual dots or lines are written sequentially, even the most complex devices could be realized quickly and easily. This method is now also available for optical elements.

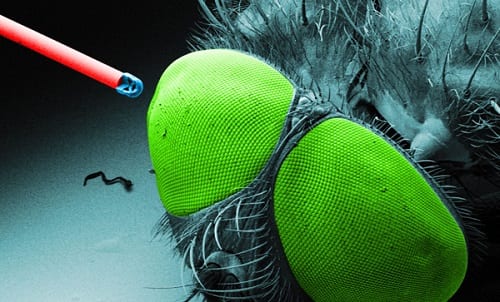

Complex 3D printed objective on an optical fiber next to a fly. Source: University of Stuttgart

Researchers at University of Stuttgart in Germany have used an ultrashort laser pulses in combination with optical photoresist to create optical lenses that are hardly larger than a human hair.

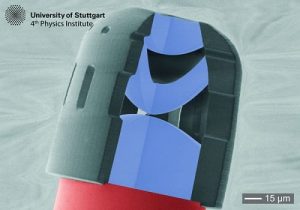

PhD student Timo Gissibl in the group of Prof. Harald Giessen at the 4th Physics Institute printed micro-objectives with a diameter and height of only 125 µm, even on optical fibers. This permits the construction of novel and extremely small endoscopes which are suited for smallest body openings or machine parts that can be inspected. The optical design was realized in the Stuttgart Research Center for Photonics Engineering by Ph.D. student Simon Thiele from the group of Prof. Alois Herkommer at the Institute of Technical Optics in Stuttgart.

Complex triplet lens by femtosecond 3D printing on a single mode optical fiber. Source: University of Stuttgart

Timo Gissibl also printed optical free form surfaces and miniature objectives directly onto CMOS image chips, which thus create an extremely compact sensor. Using such optics, smallest cameras from drones that are not larger than a bee are possible. Also, the smallest sensors for autonomous cars and robots are conceivable. Even smallest body sensors and surround-cameras for cellphones could be realized.

The Stuttgart researchers believe that 3D printing of optics is going to open an entire new era of optics manufacturing. “The time from the idea, the optics design, a CAD model, to the finished, 3D printed micro-objectives is going to be less than a day”, states Harald Giessen. “We are going to open potentials just like computer-aided design and computer-integrated manufacturing did in mechanical engineering a few years ago”.