High energy density permanent magnets are key components in a wealth of systems, ranging from sensors to actuators. While magnetic materials are crucial to the development of technologies for robotics, renewable energy, aeronautics, and automotive engineering, their processability is limited. However, 3D printing can overcome the challenges of current manufacturing processes for magnetic-based materials, as it enables the easy construction of complex architectures to enhance performance and production.

Current manufacturing methods for these types of materials, such as injection molding and sintering, face several obstacles, particularly in the production of complex geometries. Injection molding offers significant design freedom but the technique cannot be used to form multi-component devices with a complex combination of materials. Sintered magnets require the use of pressing tools, which limits complexity. Post-processing machining is also challenging, as hard-magnetic materials are usually brittle, pyrophoric, and prone to cracking.

By exploiting the capabilities of 3D printing, high performance composite magnets can be precisely patterned into complex shapes and architectures. In addition, custom magnets can be tailor-made for specific applications and directly printed into the desired structure, minimizing additional costs of further assembly of parts and components.

By exploiting the capabilities of 3D printing, high performance composite magnets can be precisely patterned into complex shapes and architectures. In addition, custom magnets can be tailor-made for specific applications and directly printed into the desired structure, minimizing additional costs of further assembly of parts and components.

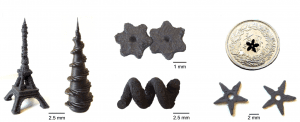

In a collaborative study between researchers at the Multi‐Scale Robotics Lab (MSRL), Institute of Robotics and Intelligent Systems (IRIS), and ETH Zurich, Dr. Salvador Pané and colleagues report the production of a variety of 3D thermoplastic-bonded magnetic composites with complex shapes (see figure right) and tunable magnetic properties, demonstrating the efficiency and high degree of complexity that can be achieved using a new fused deposition modelling 3D printer.

“The use of 3D printing for magnetic applications represents a leap towards on-site versatile fabrication of complex magnetic devices, which would otherwise be unfeasible with conventional manufacturing techniques,” says Dr. Salvador Pané, project lead.

The composites are made of polyamide and contain magnetic particles of different sizes and magnetic behavior through which the researchers were able to adjust the magnetic properties of different printed structures.

Most impressively, the team also successfully showed the versatility of their 3D printer by fabricating magnetic gearboxes with different configurations that contained both magnetic and non-magnetic components and required no further assembly after printing. Their potential as magnetic rotatory encoders (a sensor of mechanical motion that generates digital signals in response to provide information with regards to position, velocity and direction), which are key components in industrial robotics, was also demonstrated.

While an exciting step forward, future work is aimed toward overcoming challenges in the miniaturization of these structures and improving their mechanical features.

Kindly contributed by the authors.