A team of scientists has developed a method of using organisms called microalgae, a microscopic phytoplankton typically found in freshwater and marine systems, to create inks for 3D printing. The platform offers more environmentally friendly building blocks for the burgeoning 3D printing market.

3D printing is a computer-controlled process that creates 3D objects by depositing solid materials additively, often layer by layer, using light or laser scanning — the solid material is derived from liquid inks or resins.

3D printing has become increasingly important in industries that use complex parts to complete products. This includes the creation of medical devices, the automotive industry, aerospace, and even accessibility. Not only is 3D printing also on the rise in the home, but it is even being used now to create modular houses.

Many challenges face the 3D printing industry as scientists seek to boost the speed of the process and also enable the creation of even finer feature sizes, as well as making 3D laser printers more compact and less expensive.

One major problem is currently facing this additive manufacturing procedure is the fact that 3D printing inks often rely on petroleum-based monomers and other additives. Not only are these not environmentally friendly, they can even be toxic.

This has led to the search for more environmentally friendly 3D printing inks and resins with a wealth of different materials currently being investigated. This research suggests that the solution to this issue already exists in nature in the form of microalgae that could serve as a renewable biomass source instead of fossil fuel-derived materials.

Green 3D printing with microalgae

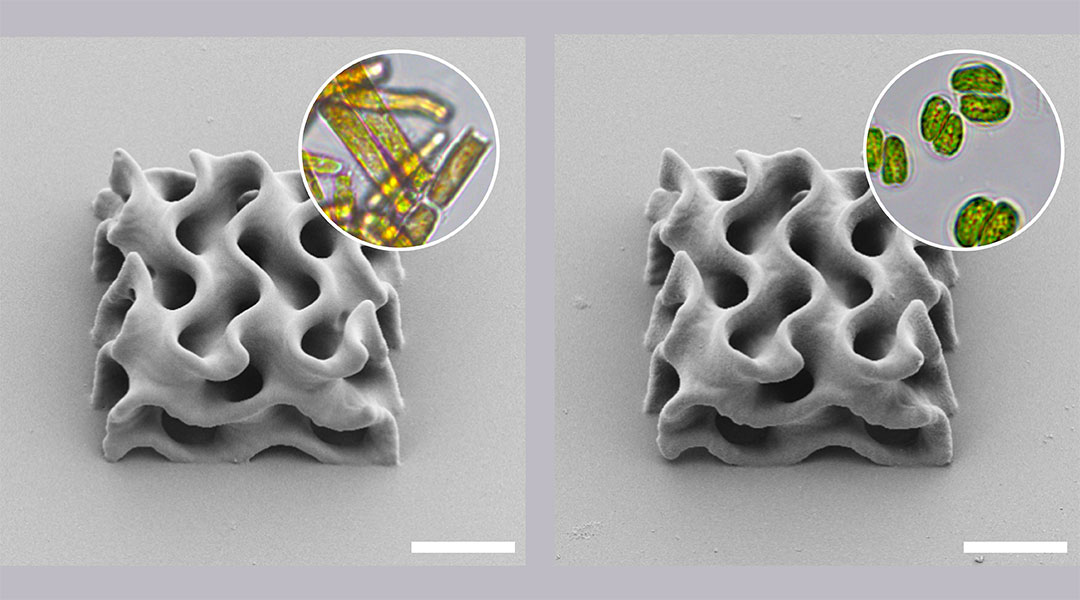

The team’s research, published in the journal Advanced Materials, suggests that two strains of microalgae, Odontella aurita (O. aurita) and Tetraselmis striata (T. striata), could be used as “biofactories” that can generate materials that can be 3D printed in high resolution.

“Extracts from microalgae can be used as printable materials (inks) for 3D printing with high resolution using a laser-based technology called two-photon 3D laser printing,” explained Eva Blasco of Heidelberg University, Germany, and PI at the Excellence Cluster 3D Matter Made to Order (3DMM2O). “Microalgae can be seen as microscopic biofactories for the next generation of sustainable, biobased, and biocompatible materials that have the potential to revolutionize materials science.”

Blasco continued by explaining that microalgae-based inks could overcome the environmental drawbacks of current products by providing a more sustainable and eco-friendly alternative to petroleum-based 3D printing materials.

The new approach is environmentally friendly because during their cultivation, microalgae can perform “carbon fixation” converting atmospheric carbon dioxide into organic molecules. Additionally, microalgae do not compete with food crops for arable land, unlike some plant-based bioplastics.

Blasco said this makes them a more viable option for large-scale production without impacting food supplies. Furthermore, the cultivation of microalgae doesn’t require fresh water, meaning wastewater can even be used, thus offering interesting alternatives to wastewater treatment routes. She added that printed materials derived from microalgae are biocompatible, opening new possibilities in bioengineering applications.

The team was particularly interested in fatty and hydrophobic organic compounds in the microalgae called lipids, especially those mainly composed of triglycerides, the main constituents of body fat in humans and other animals, as well as composing vegetable fat. Not only does microalgae grow faster than other vegetable oil crops, but the lipid yield of these organisms is greater, too.

Blasco added that in the case of microalgae, these fatty acids are highly unsaturated, meaning they have two or more carbon atoms that are joined by a double or triple bond, which means that they can be combined with additional atoms or radicals. The double bonds of these unsaturated fatty acids can thus be used for functionalization with printable groups.

“The idea of using microorganisms as biofactories for the generation of functional materials, especially in the field of 3D printing, is unexplored,” Blasco said. “Furthermore, microalgae are a unique feedstock since they contain interesting metabolites for both monomers and photoinitiators that can directly yield inks for 3D printing without relying on external and often non-biobased additives.”

The material devised by the team showed excellent biocompatibility, allowing 3D printing without the addition of photoinitiators, molecules that absorb photons when light is shone on them and form reactive species out of the resultant excited state, which can then initiate further reactions.

“The fact that the microalgae inherently contained green pigments, such as chlorophyll derivatives, which could successfully replace conventional photoinitiators, was quite surprising,” Blasco said. “This opens new opportunities in applications in life sciences since ‘standard’ photoinitiators are usually toxic.”

Scaling up the ink

The team’s microalgae alternative performed very well during testing, successfully creating 3D microstructures with sub-micron resolution. Its performance was comparable to current 3D printing inks and resins for two-photon 3D laser printing.

“The presented approach worked for two microalgae from different families, namely O. aurita and T. striata, demonstrating its versatility, broad applicability, and thus its impact,” said Clara Vazquez-Martel, first author of the publication and a Ph.D. candidate in Blasco’s group. “Other microalgae strains would probably be suitable as well and should be explored in the future.”

She continued by explaining that the developed method is quite easy and straightforward, meaning that it could easily be scaled up for use outside of the lab.

“Our partners at the Spanish Bank of Algae are already working with photobioreactors of different volumes as well as raceways-type culture tanks for even bigger-scale cultivation,” Vazquez-Martel said. “We are also considering exploring other techniques that can accelerate the whole process. To move towards a perfect circular materials economy, we want to investigate the biodegradability as well as end-of-life purposes of 3D printed structures.

“If we manage to close the loop, microalgae-based materials would be used, and, after their functional lifetime, these materials can degrade on-demand, for example, generating nutrients for the next cycle of microalgae cultivation.”

Reference: E. Blasco, et al., Printing Green: Microalgae-Based Materials for 3D Printing with Light, Advanced Materials, (2024). DOI: 10.1002/adma.202402786