Culturing cells, the process of growing cells under controlled conditions outside of their natural environment, is an extremely important biological technique that allows researchers to study vital details of physiological processes such as aging, metabolism, and the development of various diseases.

In recent years, scientists have begun to use 3D printing, also known as additive manufacturing, which has made it possible to create intricate 3D objects with complex shapes that would otherwise be impossible to produce using traditional manufacturing methods. This technology has already revolutionized industries ranging from aerospace to the food industry to healthcare, particularly in the realm of tissue engineering and biomedical research.

Now, in a study published in Advanced Functional Materials, a team of French scientists have employed specialized materials and a unique 3D printing technique to recreate a cellular environment that closely resembles human tissue, with the potential to significantly increase the accuracy and reliability of cellular research.

Mimicking tissue with 3D printing

To achieve the desired size and shape for simulating the cellular environment within the body, the researchers employed a 3D printing technique known as two-photon polymerization.

In this method, a material is irradiated at a specific location with a laser beam. Those molecules that are struck by the light absorb two photons each and combine to form much larger molecules called polymers. The resulting substance composed of these polymers exhibits increased solidity. Any excess material from the sample not required for constructing the desired 3D structure is subsequently removed through a washing process.

“Two-photon polymerization is the only 3D printing method that allows the creation of complex 3D structures the size of a few microns with a resolution smaller than 1 micrometer,” explained Roxane Pétrot, first author of this study and a former Ph.D. student at Université Grenoble Alpes, in an email. “Here, we’re making structures to use with cells, so we need to be at the same scale, and two-photon polymerization provides a way to manufacture multiples objects in a few hours, allowing for prototyping and tests.”

The material the team used is called gelatin methacryloyl, which mimics the consistency and texture of muscle tissue, providing an excellent artificial environment for the cells. But the scientists also wanted to be able to simulate the natural deformation that occurs during movement.

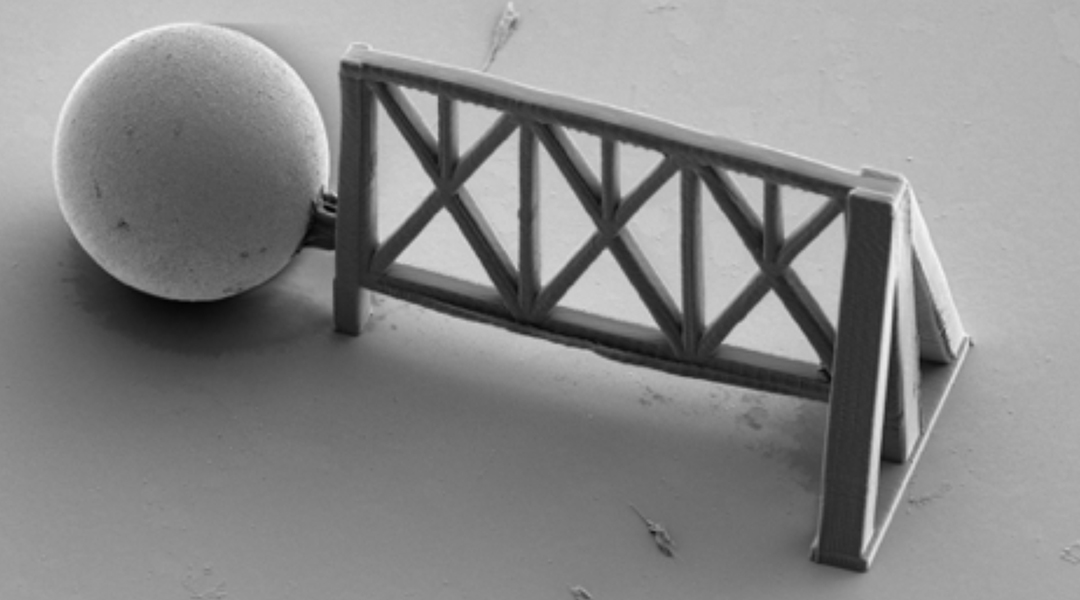

This wasn’t possible with just the soft gelatin methacryloyl, which is too pliable to be precisely molded. To overcome this limitation, they used a sturdy scaffold, the shape of which they could control by applying a magnetic field. This allowed them to affix the soft material to the framework, facilitating the safe manipulation of its shape within a fairly wide range.

“Our goal was to do cell culture on deformable structures,” said Caterina Tomba of the Institut des Nanotechnologies de Lyon and one of the authors of the study. “Thus, we decided to use two materials: One is gelatin-collagen-based hydrogel [for cell growth], modified to be polymerized with the laser light of the 3D printer, and […] an inner skeleton.”

First successful tests

The team built their skeleton from a commercial silica-based hybrid polymer called OrmoComp, which they shaped also using two-photon polymerization.

“Ormocomp is glass-like when hardened, but can still be deformed at this small scale, so it is well adapted for our use,” added Tomba. “The point-by-point polymerization allows a precise local control of the printing, providing an easy connection of the OrmoComp and gelatin structures to the magnetic beads, which are necessary to deform the micro-objects by applying an external magnetic field.”

To test if the artificial tissue structures they created worked as they should, the scientists attempted to culture cells with them. Over a span of just three days, they observed cell growth, albeit with some unexpected variations in shape of the 3D printed scaffold, which they attributed to certain gelatin-related printing issues they aim to address.

In the future, the researchers plan to increase this period to ensure that their technology is suitable for conducting accurate and large-scale cell studies.

Tomba indicated that the team is going to improve their method in order to quickly create even more complex structures necessary to simulate the environment of cells in various organs. This advancement holds the promise of facilitating in-depth studies of processes occurring in different regions of the human body, potentially unlocking insights into aging and enhancing treatments for various diseases.

“We want to be able to fabricate multiple structures in parallel in order to increase the statistics of the biological studies and to design more complex structures mimicking different organs,” Tomba said.

“Therefore, the application of these structures is either to replicate curved dynamic tissues in vivo such as the intestinal barrier or the lung bronchi and to conduct more investigations to better understand their formation and functions, or for other applications in the micro-actuator field,” she concluded.

Reference: Stéphan, Olivier, Tomba, Caterina, et al., Multi-Material 3D Microprinting of Magnetically Deformable Biocompatible Structures, Advanced Functional Materials (2023). DOI: 10.1002/adfm.202304445

Feature image: A SEM image of a 3D printed structure (OrmoComp skeleton and the magnetic bead). Credit: Caterina Tomba, et al.