Aerospace, electronics and communication devices often require methods for heat dissipation, including heat sinks, heat spreaders or thermal interface materials. Due to rapidly increasing power densities in modern devices, effective thermal management is vital for improving performance and reliability.

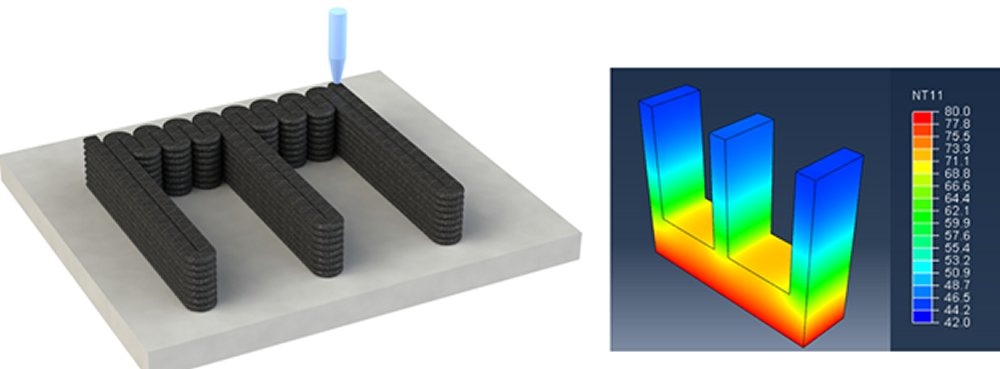

Recently, advances are being made for developing effective and low cost thermal management devices using advanced and scalable manufacturing techniques, such as additive manufacturing or 3D printing. Additive manufacturing involves computer aided design and printing materials preparation for building 3D structures. This emerging technology is capable of fabricating various types of structures using a variety of materials from metals, ceramics, to polymers. 3D printing methods could reduce processing time, and have the potential for fabrication of complex 3D and net shapes with better performance for thermal management applications.

The goal of this work published in Advanced Engineering Materials is to highlight recent research results in fabricating thermal management devices using 3D printing methods. The authors summarized interesting case studies of materials preparation and printing techniques for thermal management application, such as heat sinks, heaters, or thermal interface materials.

In the paper, Jin Gyu Park and co-workers from Florida State University discuss different printing principles including direct write printing, fuse deposition modeling, and laser-based sintering printing. Several new materials, such as graphene, boron nitride, carbon-based materials, and silver nanowires are also addressed in the review.

In addition thoughts regarding some promising outlooks in terms of combination of 3D printing with other methods to fabricate smart and lightweight thermal devices are presented. Current challenges in printing techniques as a new fabrication approach for thermal devices are also discussed in the paper.