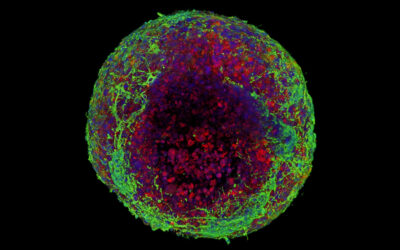

One of the main goals of researchers working in the field of tissue engineering is to prepare scaffolds that can mimic the tissue microenvironment. To this end, polymeric micro- and nanofibers have been used extensively. However, conventional methods of making these fibers lack the capacity for fabricating highly organized networks with controlled uniformity and orientation.

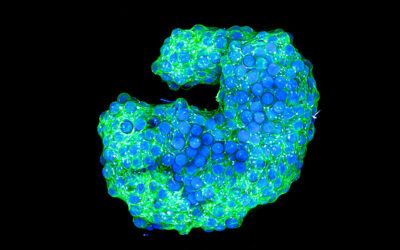

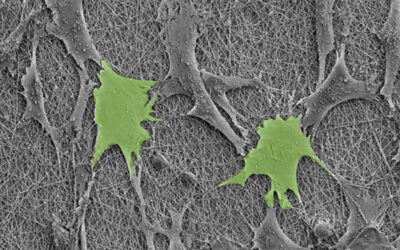

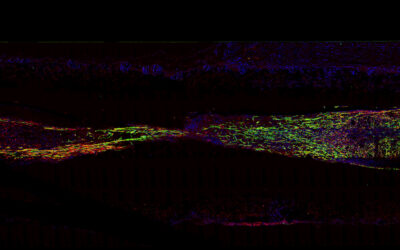

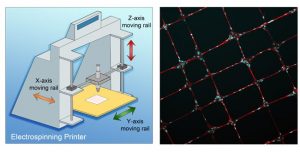

Brown and colleagues, at Pennsylvania State University (USA), describe a new method to tackle the challenges of producing highly aligned 3D fibrous structures. Their approach, published recently in Advanced Healthcare Materials, is called 3D near field electrospinning (3DNFES) as it combines near-field electrospinning with 3D printing. This automated strategy enables large-scale production of highly organized fibers with pre-designed patterns allowing the combination of all three directions of X, Y and Z. The so-prepared fibers support stem cell growth and are suitable for deposition in cell-loaded collagen gels, improving material properties and cell alignment within. 3DNFES proves to be a simple, inexpensive, high-throughput technology with precise control over fiber fabrication and will be beneficial in fabrication of numerous 3D nano- and microscale scaffolds with applications in a variety of areas including biomedicine as well as electronics and optics.