The recent rise of 3D printing, which allows for the creation of objects with complex 3D geometries, has shaken up many areas of science and industry, including medicine, electronics, and food production, among others. This fabricating technique has found such widespread use as it can significantly reduce the time required to create a product, allowing detail and shape that is not possible with other production methods.

While an incredibly powerful and useful technology, 3D printing is usually constrained to the production static structures, while researchers have long been interested in creating objects that have the properties of living organisms, such as adaptability, continuous growth, and regeneration.

To pave the way for the production of such objects, a group of Chinese scientists led by Ning Zheng and Tao Xie proposed using 4D printing.

“Typical 3D printing produces static 3D shapes,” explained Xie, a professor at Zhejiang University, in an e-mail. “In contrast, 4D printing produces dynamic structures that can evolve with time (the fourth dimension) after the printing.”

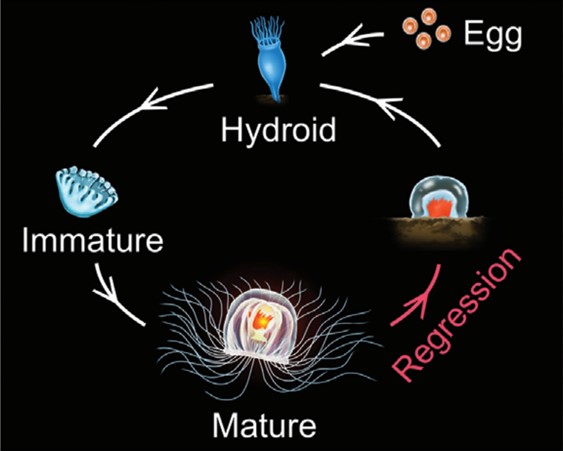

The creature that inspired the scientists in their endeavors was the immortal jellyfish, Turritopsis nutricula. In their normal life cycle, eggs develop into an intermediate organism called a hydroid, which then mature into adult jellyfish. Under certain conditions, such as during food shortage or after enduring physical damage, immortal jelly fish can revert from their mature state back to hydroids, and after a time, mature again.

It is this complex and changeable life cycle of a jellyfish that the researchers have tried to reproduce using 4D printing.

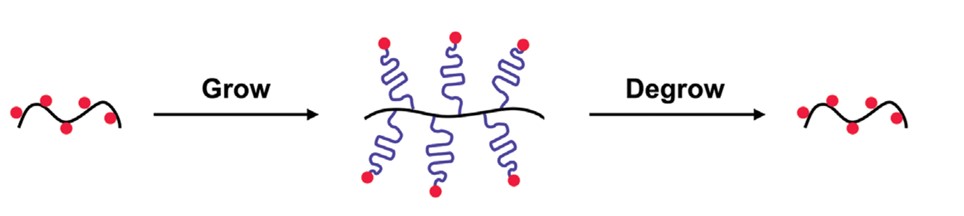

For their ink, the researchers used a polymer, a class of materials made up of very large molecules, composed of linked chemical units called monomers. Polymers are found in both synthetic and natural materials, with perhaps the most famous example being the DNA double helix, which stores genetic information in the cells of living organisms.

“Most examples of 4D printing are related to organic polymers because they can be designed more easily to undergo large shape-change (or time evolution of shapes),” explained Xie.

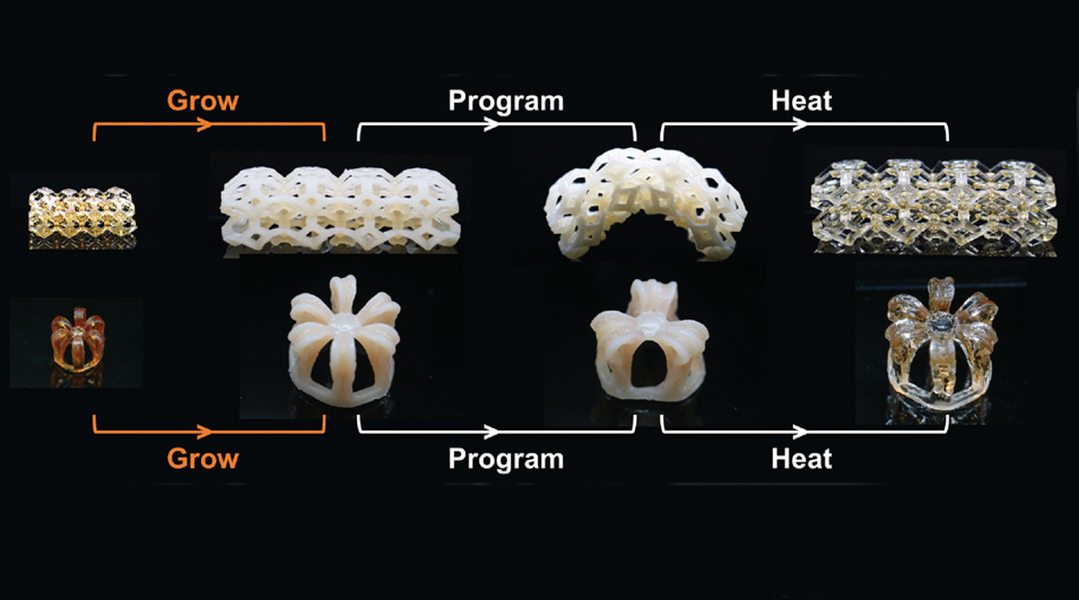

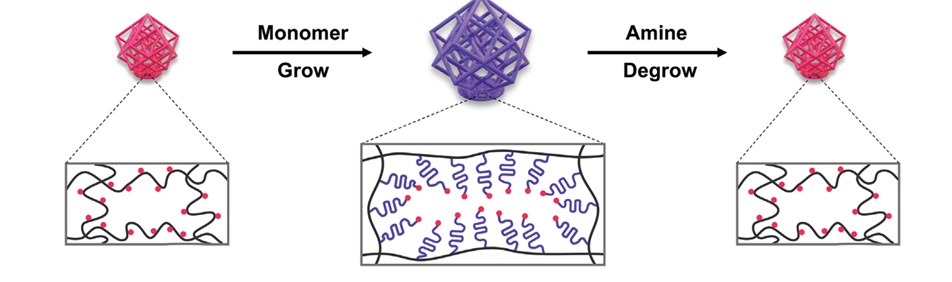

The 4D printing process the team studied began by placing an amorphous “seed” green body into a specially prepared mixture called a resin, which was composed of monomers. Then, under the influence of light, the molecules of the seed material interacted with the resin monomers, forming the desired polymer chains. The result of this polymerization was an object corresponding to a mature jellyfish.

Once the polymer chains were grown, the larger molecules can be brought back to their original form by bringing them into contact with an amine, which cleaves the chemical bonds between the original molecules and the monomers they took from the resin. This interaction can be localized to control shape changes by exposing only certain areas of the printed sample to the amine.

By performing a large number of cycles of growth/localized degrowth/regrowth, the scientists were able to obtain samples of very different shapes with differing mechanical and thermodynamic properties, all starting from the same green body.

Compared to conventional 3D printing techniques to create similar structures, the time required for manufacturing turned out to be many times less.

“The study at this point is very much curiosity driven,” concluded Xie. “For the future, we would really like to expand the principle and material choices as guided by practical needs.”

Reference: Ning Zheng, Tao Xie, et al., Regenerative Living 4D Printing via Reversible Growth of Polymer Networks, Advanced Materials (2023). DOI: 10.1002/adma.202209824

Feature image credit: Eugenia Clara on Unsplash