Fiber-reinforced plastic is the most common for electronic circuits, but modern electronics require a flexible, biocompatible alternative that also facilitates device fabrication.

In their paper in Advanced Functional Materials, Giuseppe Cantarella from the Swiss Federal Institute of Technology, and his co-workers report the fabrication of a mesa-shaped elastomeric substrate that serves as support for flexible, biocompatible electronics.

Giuseppe Cantarella: “The basic concept is to realize a nearly flexible substrate shape with mesa or pillars. These high-relief structures are designed to mechanically decouple the strain applied onto the flexible substrate from the one experienced by the electronics on top of the pillar surface.”

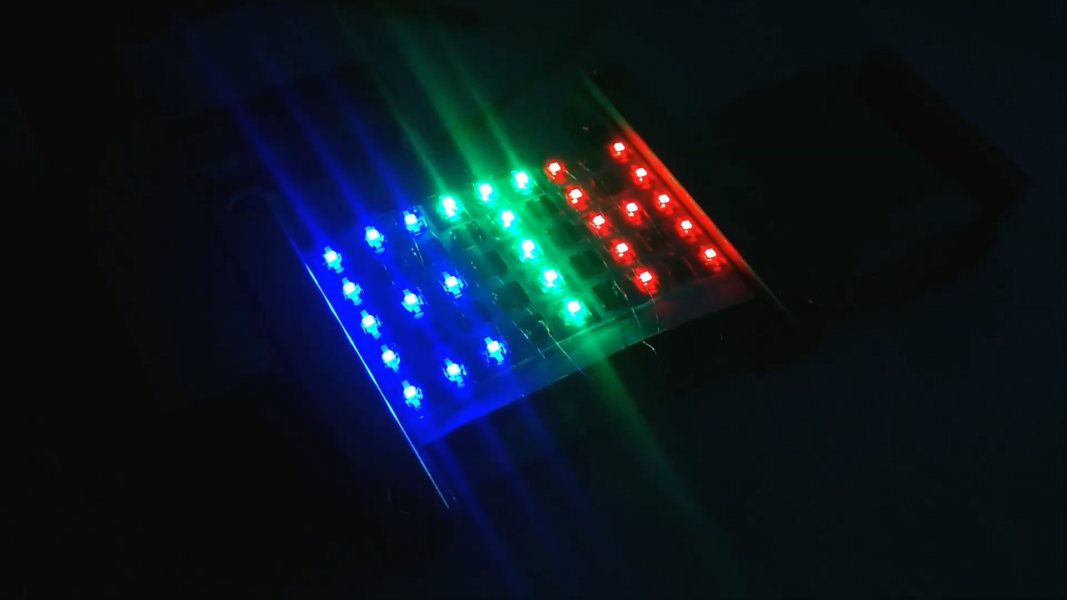

The mesa-like layout of the substrates allows the devices to withstand bending, stretching by up to 20%, and up to 180° twisting. Light-emitting diodes mounted on the pillars remained functional while being bent or stretched.

A pectin-based temperature sensor demonstrates the versatility of the approach.

Vincenzo Constanza: “Pectin is a molecule extracted from plant cells that can be used to fabricate thin films with a high temperature response. However, these films are brittle and non-stretchable. The combination of rigid islands coated with pectin and soft areas allowed us to fabricate a stretchable temperature sensor, working up to 15% of applied strain, for applications in wearable devices and electronic skins.”

To learn more about this highly versatile substrate for flexible electronics, please visit the Advanced Functional Materials homepage.