One of the major issues facing our society is the shortage of clean drinking water. Fog collection is seen as an attractive solution due to its large water capacity. Many plants belonging to the Cactaceae species live in arid environments and are extremely drought-tolerant due to their special moisture collection abilities of the multi-scale directional cactus spines. The gradient of surface‐free energy and gradient of Laplace pressure are the primary driving forces behind these phenomena.

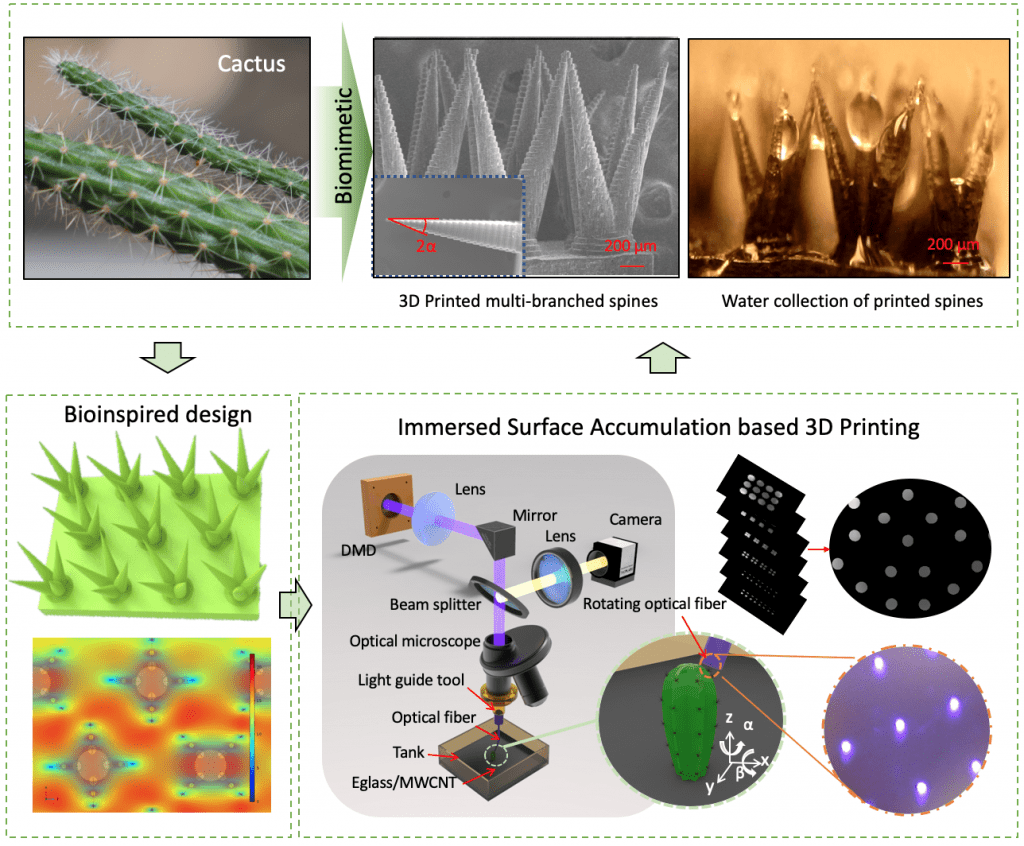

The fog collection mechanism used by the cactus has provided inspiration for constructing energy-efficient and environmentally friendly water collection devices. However, this technique has reached a bottleneck when it comes to improving collection efficiency because it is hard to replicate the natural clusters of branched spines found in cacti using traditional manufacturing methods. The fabrication of multi-spines arrays with controllable arrangements that mimic those found in nature is challenging.

In a study published in Advanced Materials Interfaces, Professor Yong Chen from the University of Southern California and co-workers reported a 3D-printed, cactus-inspired spin structure for highly efficient water collection. An immersed surface accumulation–based 3D-printing process was developed to reproduce branched cactus spines, enabling the study of water collection of artificial spines with various designs.

Their collector contains microscale, biomimetic spines with controllable tip angles and wettability, which was shown to significantly improve the material’s water collection efficiency.

The underlying mechanism of the superiority of the 3D-printed, cactus-inspired spine structures includes a more turbulent and complicated flow field around the optimized spines, which increases their effective deposition area, facilitating more tiny water droplet deposition and resulting water collection.

The team believes that the results will be helpful in further understanding the effect of geometrical morphology of artificial 3D structures on the water condensation and transportation. “As an environmentally-friendly device, the new energy-efficient surface with the optimised biomimetic multi-branched spines fabricated by 3D printing technologies has prospective applications in water collection, water transportation, and oil-water separation,” said Chen.

Research article available at: X. Li, et al. Advanced Materials Interfaces, 2019, doi.org/10.1002/admi.201901752