Image credit: Gunter Valda on Unsplash

Researchers at Carnegie Mellon University have 3D-printed the first full-sized human heart model using the new freeform reversible embedding of suspended hydrogels (FRESH) technique.

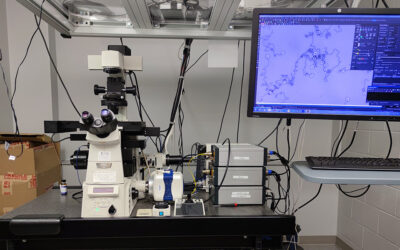

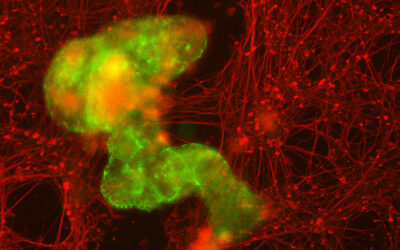

Professor Adam Feinberg and his team at the College of Engineering at Carnegie Mellon invented the FRESH technique as a way to address current obstacles in 3D printing for medical purposes. Whilst 3D printing based on MRI scans for training purposes is nothing new, current technologies are limited by the models being made of rigid plastic or rubber. The FRESH technique, on the other hand, can 3D print soft materials that better mimics biological tissue, allowing for a more realistic model — for example of a patient’s heart — for trainee surgeons to practice surgical techniques such as suturing.

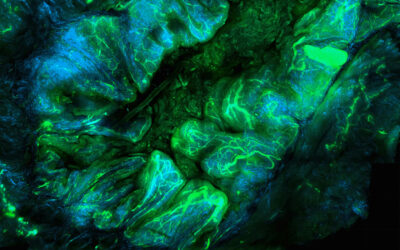

FRESH 3D printing works by taking an MRI scan of a real patient’s heart and using this digital model as the input for the FRESH 3D printer, which starts by injecting a bioink — the printing material — into a bath of soft hydrogel, which acts as a support for the object whilst it’s printing. Once finished, simply turning up the heat melts away the hydrogel, leaving only the 3D bioprinted object behind.

This unique method is the culmination of two years of work by Feinberg and his team, and now their work — published in ACS Biomaterials Science & Engineering — has proven to be a success, they are keen to roll it out soon in real clinical settings.

Advances in 3D bioprinting of a patient’s heart caused a stir last year, where the “material” was the patient’s own cells. This FRESH-technique is another big milestone in the quest toward manufacturing fully functional organs without the risks associated with traditional transplants, such as rejection by the body caused by immune responses.

“While major hurdles still exist in bioprinting a full-sized functional human heart, we are proud to help establish its foundational groundwork using the FRESH platform while showing immediate applications for realistic surgical simulation,” said Eman Mirdamadi, lead author on the publication, in a press release.

To see this technique in action, the American Chemical Society has also showcased the work in a recent video.