From the defogger on car windshields to aircraft windows and supermarket refrigerator displays, electrical conductors keep the glass clear. They do this by providing resistance to an electric current, heating the glass in the process.

In Advanced Materials, Dr. Xiaoyang Zhu and Prof. Hongbo Lan of Qingdao University of Technology, and their co-workers report a new silver mesh fabrication technique that improves the performance of transparent glass heaters (or TGHs).

The new TGH is fabricated over four steps. Firstly, an electric-field-driven, microscale 3D printer is used to make polymer-based microlines. These microlines are used to template a mold. Next, a silver paste is scraped into the mold and cured at low temperatures.

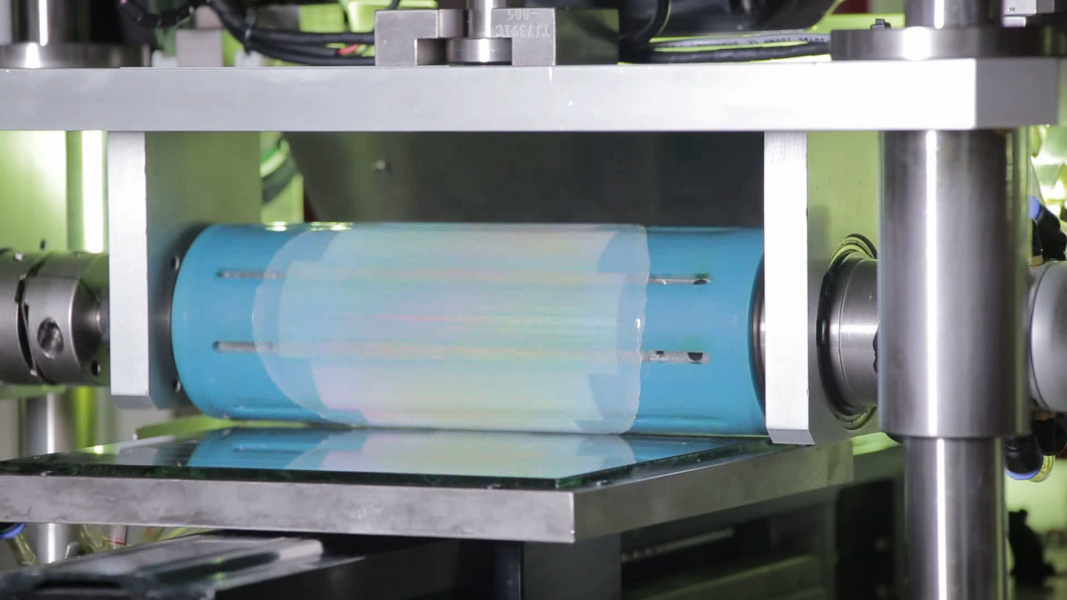

The molded silver paste is then transferred to a pane of glass using a roller-type, line-contact imprint process, and a post-processing step ensures that the conducting wire adheres properly to the surface.

The new TGH was found to have excellent transparency, allowing more than 90% of light through. In most commercially available TGHs, good transparency comes at the cost of effective electrical resistance. However, this design also allows for high electrical conductivity that is stable over time.

To find out more about this high-performance transparent glass heater, please visit the Advanced Materials homepage.