The future of technology relies on devices that integrate multiple functionalities into one system. As the number of functional components increases, however, simultaneous control over the components becomes a challenge.

In an article published in Small, Prof. Xiangyi Zhang from Yanshan University and his co-workers report a novel strategy that enables them to precisely design and assemble bulk, multicomponent nanostructures with ideal structures.

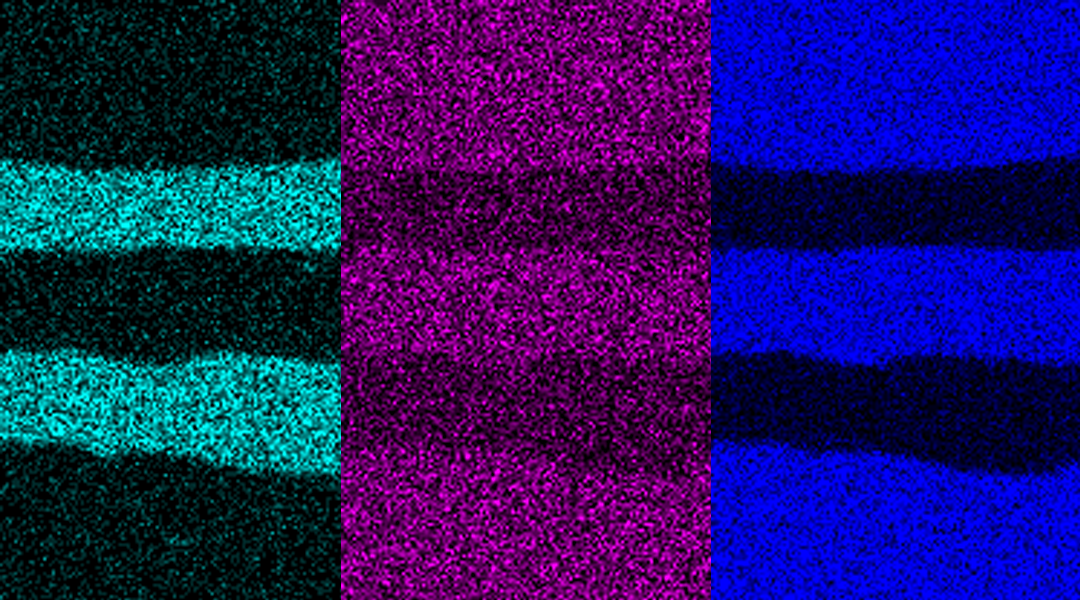

Amorphous precursors were mixed with nanocrystalline precursors, and the bulk sample was deformed by high-pressure thermal compression to yield a multicomponent nanostructure consisting of alternating layers of nanograins. One layer contains a mixture of samarium–cobalt and iron–cobalt nanograins, and the other is composed of neodymium–iron–boron nanograins. Such a layered structure enables the components to have their ideal structures.

Magnetic measurements indicate that the multicomponent nanostructure has a large energy density of 31 MGOe compared to 24 MGOe for the two-component system, which is a record-high for this class of bulk nanocomposite magnets with high soft magnetic fractions. The magnetization curves of the two nanostructures reveal that a multistep magnetization process occurs for the layered, multicomponent nanostructure.

No degradation of the magnetic properties was observed after annealing, indicating that the bulk, multicomponent nanostructure has good long-term thermal stability.

To find out more about this strategy for engineering bulk, complex, hybrid nanostructures, please visit the Small homepage.