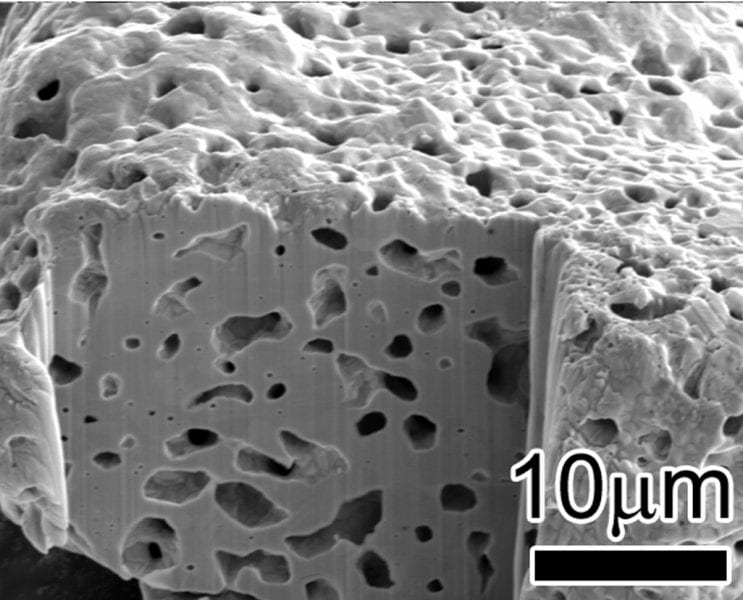

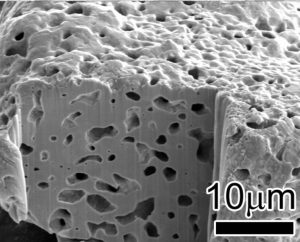

Solid state processing for creating metal foams is often used when liquid state processing is not viable, but such processing results in an accompanying inferior level of porosity. In a step away from convention, a new method for creating a high degree of porosity within powder particles has been reported by US-based scientists, termed AERO (Additive Expansion by the Reduction of Oxides). While the current state-of-the-art foaming processes only rely on expansion between particles, the AERO process incorporates expansion within the particle upon heating as well.

Solid state processing for creating metal foams is often used when liquid state processing is not viable, but such processing results in an accompanying inferior level of porosity. In a step away from convention, a new method for creating a high degree of porosity within powder particles has been reported by US-based scientists, termed AERO (Additive Expansion by the Reduction of Oxides). While the current state-of-the-art foaming processes only rely on expansion between particles, the AERO process incorporates expansion within the particle upon heating as well.

This paradigm shift from convention has wide-ranging applicability. The broader impact is the ability to add 40% porosity to powders used in current powder metallurgy processes for metal foams. In a first demonstration, the group report a complex fully-foamed Cu-Sb sintered part with close to 70% porosity. When extended to other alloys, this technology may advance the development of custom biological implants, hydrogen fuel cells, or other complex geometries where porosity levels can be controlled or progressively graded simply by blending non-foaming powders with AERO powders.