Metal foams are cellular structures consisting of a network of stochastically distributed pores. They are a relatively new class of biomimetic materials that are similar to the construction elements of biological load-bearing structures like wood or bone. As they are able to dissipate a considerable amount of deformation energy metal foams are often used as energy absorber and structural damping elements in the aeronautic and automotive industries.

Due to its low density, low costs, and low melting point, most metal foams are made of aluminum. However, in comparison to other metals, aluminum has a very low tensile strength. Furthermore, the poor reproducibility of the mechanical properties that arises through flaws in the pore structure is a further disadvantage. Coating of the metal foams can be used to improve the mechanical properties of a substrate foam by combining the mechanical properties of the base material and the coating.

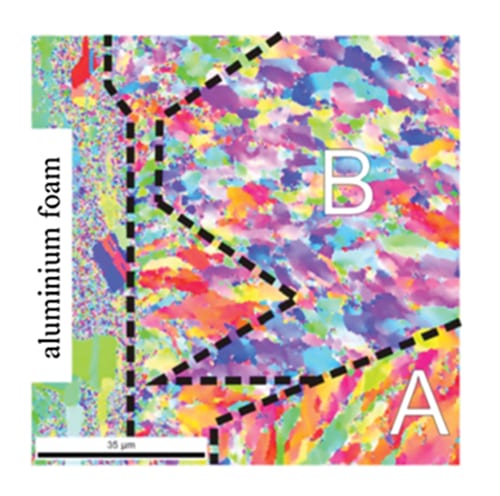

A group of scientists from the Saarland University, Germany, together with a colleague from the Norwegian University of Science and Technology, have investigated the texture and grain growth of Ni/Al-hybrid metal foams. These are new composite materials consisting of open-cell aluminum foams that have been electrochemically coated with nickel via a specially developed electro-deposition technique.

A group of scientists from the Saarland University, Germany, together with a colleague from the Norwegian University of Science and Technology, have investigated the texture and grain growth of Ni/Al-hybrid metal foams. These are new composite materials consisting of open-cell aluminum foams that have been electrochemically coated with nickel via a specially developed electro-deposition technique.

In previous work they already show that coating led to superior mechanical properties in comparison to pure aluminum foams, especially regarding stiffness, strength, energy absorption capacity, and improvement of the reproducibility of the foams. But they also indicated that for the development and understanding of such new materials, it is essential to study the texture and the grain growth in detail.

Beside other findings, their new research demonstrates that the superior mechanical properties of Ni/Al-hybrid foams are hardly related to the microstructure of the nickel coating. Directly at the Ni/Al interface there is a hard layer of very fine grains and a hardness of more than four times the hardness of aluminum.