A breakthrough in nanotechnology could revolutionize secure quantum communications. Researchers have successfully used 3D printing to create an optical system that can transmit single photons with nanometer precision. This advancement is key to enhancing quantum communication, a rapidly growing field that relies on highly secure data transmission.

Quantum communication relies on encoding information in the quantum states of photons, the basic particles that make up light and other forms of electromagnetic radiation. According to the fundamental laws of quantum mechanics, it’s impossible to measure the state of a particle without altering it.

This ensures that any attempts at eavesdropping are detectable to the communicating parties. However, while this type of security is sound in theory, its practical implementation comes with significant challenges.

The trouble with quantum communication

One of the main obstacles in quantum communications is the difficulty in producing reliable quantum emitters, though recent advances have made this more feasible.

“Quantum emitters are light sources which emit only a single photon at a time,” said Harald Giessen, a professor at the University of Stuttgart in Germany and lead author of the study, in an email. “Semiconductor quantum dots, as used in our case, are a common quantum emitter light source. Other quantum emitters include defects in hexagonal boron nitride or nitrogen-vacancy centers in diamond.”

Another major challenge is the need for extremely precise positioning of the various components within the optical device required to carry out the information exchange. If this precision isn’t maintained, information can be lost, undermining the integrity of the communication.

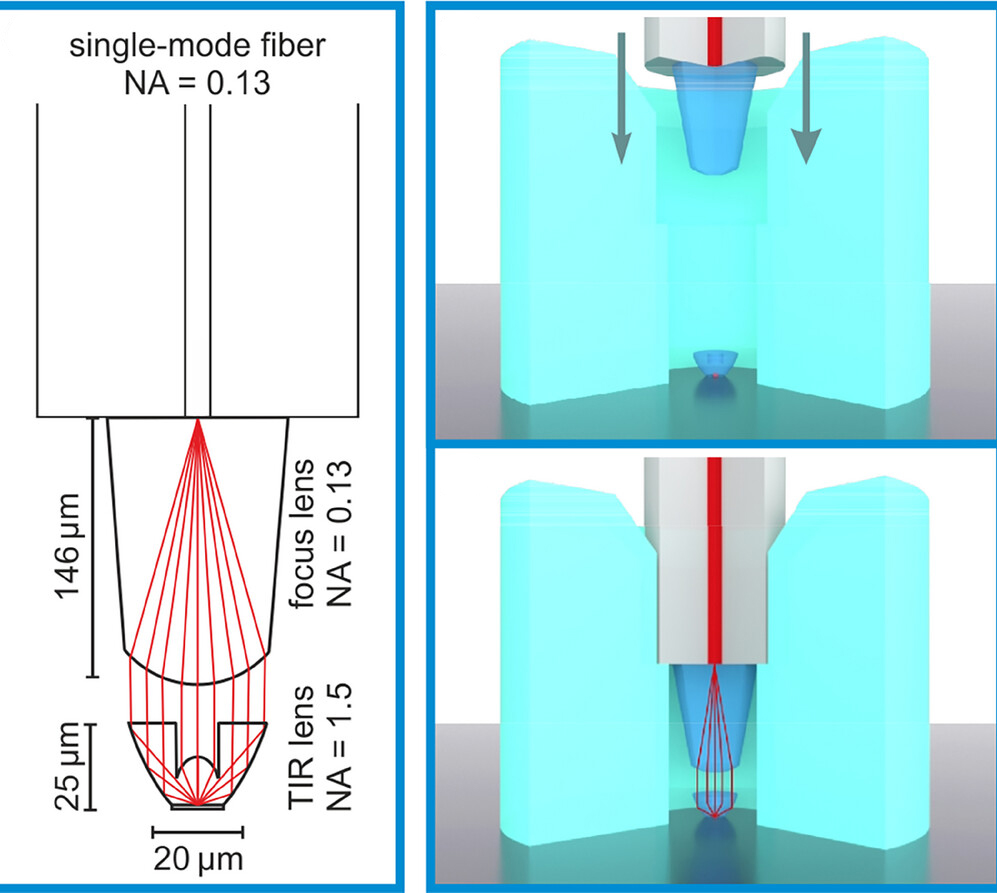

“Precise positioning of optical elements plays a key role in the performance of optical systems,” the research team wrote in their paper published in Advanced Quantum Technologies. “While additive manufacturing techniques such as 3D printing enable the creation of entire complex micro-objectives in one step, thus rendering lens alignment unnecessary.”

“For example, in order to efficiently couple quantum emitters to [optical] fibers, which is a crucial step in the development of real world quantum networks, precise alignment between the emitter, the coupling optics, and the […] fiber is of utmost importance.”

To eliminate this complexity and limitation, the team turned to the Photonics Professional GT 3D printing machine from Nanoscribe GmbH. This state-of-the-art printer is known for its ability to achieve nanometer-scale precision, making it ideal for applications in photonics and nanotechnology.

“The Nanoscribe 3D printer uses a femtosecond laser at 780 nm wavelength which is focused tightly with a high numerical aperture microscope objective into a [light-sensitive material called a] photoresist,” explained Giessen.

By moving the laser’s focus through the material in all three directions (up, down, and side-to-side), the machine can create complex 3D shapes. These shapes can be incredibly detailed, with features as small as 160 nanometers wide and 500 nanometers tall, which is much smaller than the width of a human hair.

High precision for quantum-secure networks

Using this device, they were able to 3D print a custom lens that could capture the undirected light emitted by a quantum source and shape it into a focused beam. This beam can then be focused directly onto the core of an optical fiber with the help of another lens, which was 3D-printed onto the fiber’s end. To maintain perfect alignment, the team also printed a custom chuck to securely hold the entire system together.

The 3D printer’s integrated piezoelectric stage — a precision positioning device that uses piezoelectric materials to make extremely fine movements — allowed for nanometer-level adjustments in response to an electric field. This offered the researchers the precision needed to transmit the photons at a threshold considered necessary for reliable quantum information transfer.

Earlier computer simulations had shown that reaching this transmission rate required aligning the components with accuracy better than 100 nanometers.

“We investigated the positioning accuracy of the Photonics Professional GT 3D printing machine for the fabrication of the single-mode fiber coupled single-photon source,” the team wrote. “Looking at 38 test samples, we found a lateral misalignment error of tens of nanometers in [both directions perpendicular to the light beam].”

While the team’s results mark a significant advance in creating highly precise optical systems for quantum communications, they acknowledge that further refinements are needed before these systems can be commercially deployed. Their future work aims to improve the production process to make it more efficient, reliable, and cost-effective.

“Eventually, the emission patterns of quantum dots or other quantum emitters could be automatically characterized and optimized,” Giessen explained. “Then, suitable optical components would be designed and prepared for 3D printing. An automatic alignment system, accurate to within tens of nanometers, would precisely position the optics directly onto the quantum emitters.”

“The system would then automatically insert and glue fibers with 3D-printed micro-optics, connecting the quantum emitters to single-mode fibers,” he continued. “Such a system could produce thousands of quantum nodes per day, paving the way for future quantum-secure networks.”

Reference: Ksenia Weber et al, Positional Accuracy of 3D Printed Quantum Emitter Fiber Couplers, Advanced Quantum Technologies (2024). DOI: 10.1002/qute.202400135

Feature image credit: Pixabay