The diving bell spider (a.k.a. water spider) is the only species of spider that lives almost entirely underwater. Like other spiders, it breathes air, but it has a neat trick: when submerged in water, an air bubble is trapped by a dense layer of hydrophobic hairs on its abdomen and legs. They spend most of their time in a diving bell—irregularly constructed sheets of silk and an unknown protein-based hydrogel, which is spun between submerged water plants then inflated with air brought down from the surface by the builder.

This spider inspired University of Rochester researchers to create a metallic structure that is just as water-repellent as the diving bell. According to Chunlei Guo, a professor of optics and physics, this development could lead to unsinkable ships, wearable flotation devices that will still float after being punctured, or electronic monitoring devices that can survive long-term in the ocean.

“Metals are greatly denser than water, so they would naturally sink,” he explains. “The challenge is to design an unsinkable assembly that will not just stay floating under a special condition, but instead stay floating under all conditions even after the sample is severally pierced and damaged.”

Guo and his lab developed their novel structure by applying femtosecond bursts of lasers to the surfaces of metals. The laser bursts etch intricate micro- and nanoscale patterns that trap air and make the surfaces superhydrophobic, or water repellent.

However, the surfaces lost their hydrophobic properties after being immersed in water for long periods, unlike water spiders. The difference is that the spiders trap air in an enclosed area. For Guo, that was a very interesting inspiration. “The key insight is that multifaceted superhydrophobic surfaces can trap a large air volume, which points towards the possibility of using superhydrophobic surfaces to create buoyant devices,” he notes in a paper.

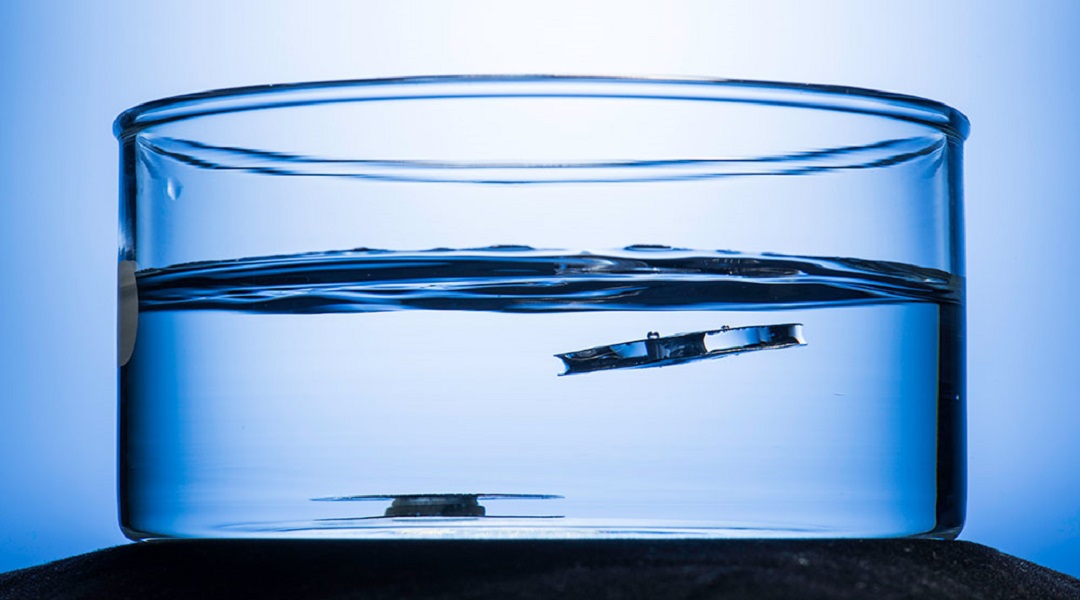

Thus, Guo’s lab created a structure in which the treated surfaces on two parallel aluminum plates face inward. The surfaces are separated by just the right distance to trap and hold enough air to keep the structure floating. The superhydrophobic surfaces keep water from entering the compartment even when the structure is forced to submerge in water. The Rochester researchers forced the specimen to submerge for two months and the structures immediately bounced back to the surface after the load was released. The air remains trapped.

When Guo’s lab first demonstrated the etching technique, it took them an hour to pattern a one-inch-by-one-inch area of surface. Now, by using lasers seven times as powerful, along with faster scanning, the lab has sped up the process, making it more feasible for commercial scale-up. And although the team used aluminum for this project, the etching process could be used for any other metal and other materials.

“We are currently designing and studying other unsinkable metallic geometries. Our study reports on super-hydrophobic surfaces. We will also explore various applications utilizing superhydrophobic surfaces,” Professor Guo stated.

Article adapted from University of Rochester press release