For a successful implementation of large area printed electronics applications thin-film transistors represent an essential basis for logic devices. Transparent conductive oxides (TCOs) have traditionally been deposited by expensive and non-digital vacuum processes, like sputtering and chemical vapour deposition. In the last years, however, many studies have been presented where the conductive TCOs have been solution-processed, in particular inkjet printed.

Printing technologies offer the advantage of being a digital, scalable and an additive technology, opening up the usage of low-cost flexible substrates. However, typical processing temperatures of >300 °C for metal oxide materials require high-temperature stable polymer substrates, like polyimide.

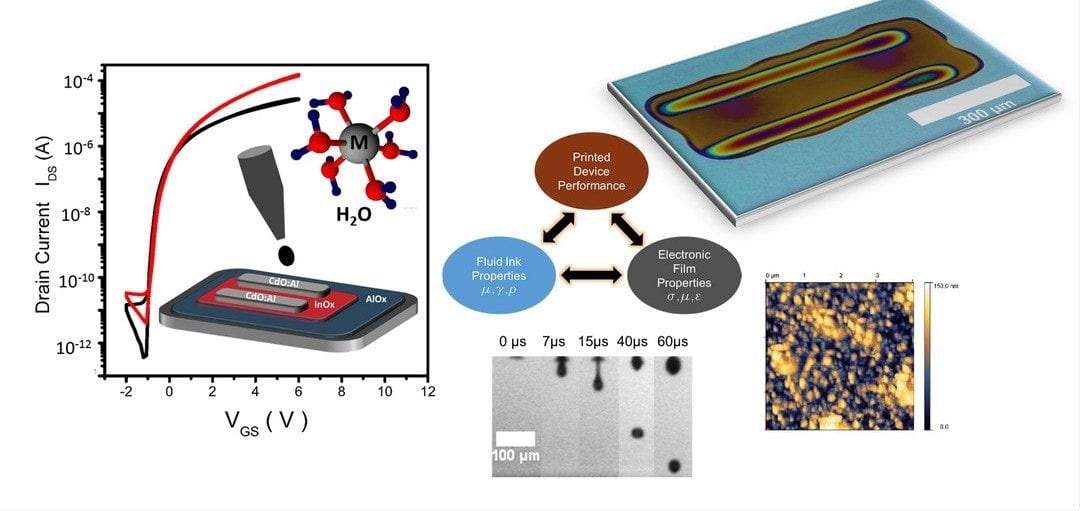

Prof. Vivek Subramanian and co-workers from the University of California, Berkeley, USA, have developed an aqueous CdO-based conductor ink formulation with a processing temperature well below 250 °C. In their recent paper in Advanced Functional Materials, they have tailored the ink’s liquid properties, like viscosity and surface tension, for the inkjet printing process and have demonstrated printed thin films of aluminium-doped CdO (ACO) as transparent electrodes and InOx as the semiconducting layer. The intrinsic fluid properties of these water-based solutions enable the printing of fine features with coffee-ring free line profiles and smoother line edges than those formed from organic solvent-based inks. As a real device, the authors demonstrated all-aqueous-printed high-performance thin-film transistors.

This demonstration emphasizes the suitability of ACO electrodes for use in oxide electronics and illustrates the extensibility of printable aqueous ink formulations to a variety of metal oxide material systems. Though the corresponding safety and environmental concerns of using cadmium are valid, CdO has exceptional electronic properties associated with its high electron affinity, high dielectric constant, and low conduction band edge. Therefore, these findings form a critical step in realising low-cost transparent electronics for display technology and photovoltaics.