Hybrid materials offer the potential to assemble attributes of two or more materials. Using the adequate constituent materials and their microstructural state in combination with the inner architecture of a hybrid, these strategies provide the opportunity of superior material design. Such an ‘architecturing’ targets multifunctional solutions where a structural component also shows functional properties such as thermal insulation, magnetism, acoustic damping, or energy absorption.

However, for these ideas to be effective, the question of feasibility of processing of such architectured materials in an affordable manner arises. Three scientists suggest that severe plastic deformation (SPD) techniques are appropriate in this field: Olivier Bouaziz, from the Ecole des Mines de Paris in France, Hyong Seop Kim, Pohang University of Science and Technology in Korea, and Yuri Estrin, Monash University in Australia. They believe that substantial breakthroughs can be expected if architecturing a materials hybrid can be combined with producing an extremely fine grain structure of its building blocks.

SPD metalworking techniques use very large strains which are imposed without changing the dimensions of the specimen or work-piece. Over the past decades they advanced to one of the most potent ways of producing bulk ultrafine grained materials. The main advantage of nanostructuring of metallic materials by SPD is the ultra-high strength they can deliver. While the improvement of the strength characteristics by SPD processing is impressive, there is a limit to what is achievable with these matured techniques when they are applied to individual materials.

SPD metalworking techniques use very large strains which are imposed without changing the dimensions of the specimen or work-piece. Over the past decades they advanced to one of the most potent ways of producing bulk ultrafine grained materials. The main advantage of nanostructuring of metallic materials by SPD is the ultra-high strength they can deliver. While the improvement of the strength characteristics by SPD processing is impressive, there is a limit to what is achievable with these matured techniques when they are applied to individual materials.

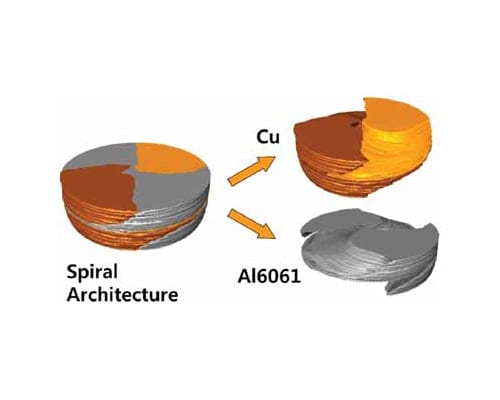

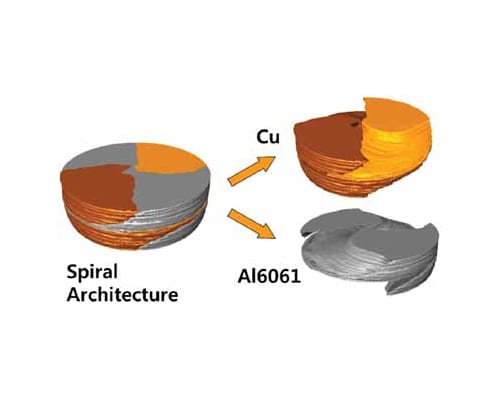

Therefore the scientists investigated a new application of SPD processes in manufacturing of architecture hybrid materials with simultaneous nanostructuring both experimentally and theoretically. One way they successfully produced material hybrids with the desired architecture was by employing high pressure torsion (HPT). A further method to achieve the architectures was by using torsion-extrusion. Varying the material combination as well as the die geometry and the processing parameters, they controlled the mechanical and physical properties of the composite.

Olivier Bouaziz and co-workers concluded that a new look at SPD processing techniques may help developing material hybrids capitalizing on the beneficial properties of individual materials with added advantages of architectured structures. Other SPD processing methods can also be utilized for geometry inspired materials design, thus opening up exciting avenues for multi-materials manufacture.