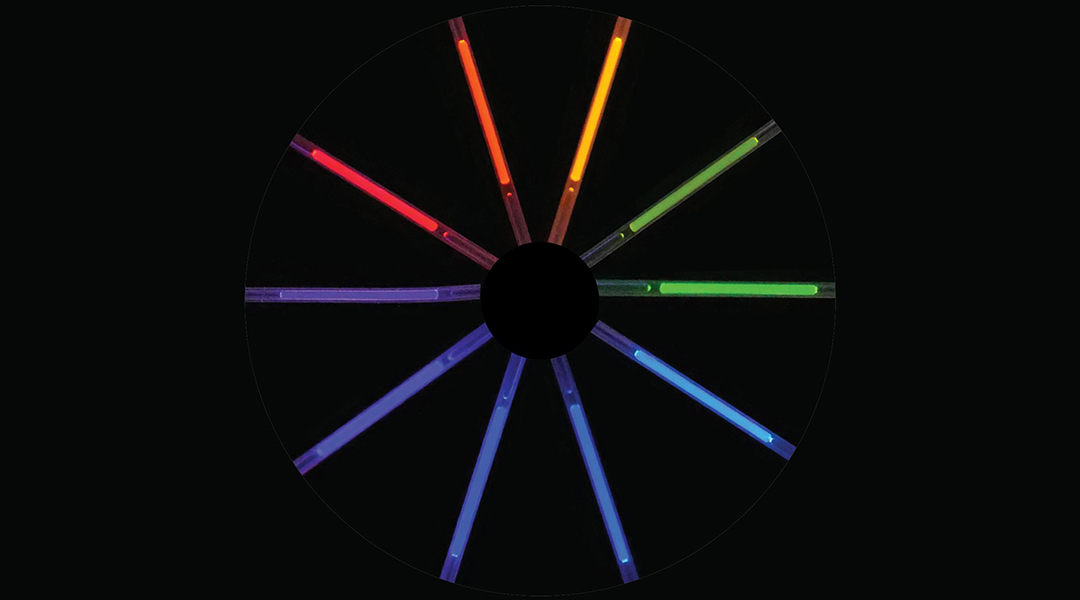

Image credit: Milad Abolhasani, NC State University

A group of researchers from North Carolina State University and the University at Buffalo have developed an intelligent robotic material synthesizer to accelerate the development and manufacturing of semiconductor nanomaterials for applications in next-generation photonic devices. This is the second generation of the Artificial Chemist technology, that is, a fluidic robo-chemist operated with an artificial intelligence (AI)-guided decision-making agent.

Artificial Chemist 2.0 starts its workflow by self-learning the multi-stage synthetic chemistry of nanomaterials, rapidly and efficiently. Its “brain” selects a set of learning experiments to be conducted autonomously by the fluidic robot, the results of which are then used to build its materials chemistry knowledge. The AI brain then identifies the best formulation of the target semiconductor nanomaterial with the desired properties, carrying this out ~1000 times faster than current manual materials development techniques.

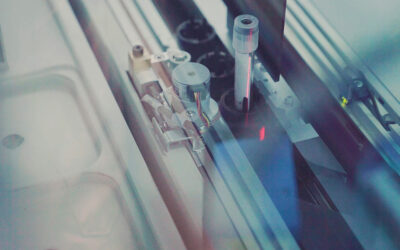

The developed intelligent robo-chemist, with its plug-and-play fluidic reactors, provides a precise and controllable material synthesis platform that uses significantly less reagents than flask-based strategies, and the integrated AI provides the means to efficiently explore the multi-stage materials synthesis space without any user intervention. Artificial Chemist 2.0 offers continuous, multi-stage experimentation as well as fully self-driven materials development, formulation optimization, and production.

Lead halide perovskite quantum dots, with their unique and highly tunable optical and optoelectronic properties, are an emerging class of semiconductor materials for applications in next-generation devices such as solar cells and LED displays, as well as photocatalytic processes. Similar to other quantum dots, the optical and optoelectronic properties of lead halide perovskites are heavily dependent on their synthesis.

In the current study — recently published in the journal Advanced Intelligent Systems — lead halide perovskite quantum dots were selected as the test bed to demonstrate the robot’s capabilities due to their complex, multi-stage synthetic chemistry and the large number of input parameters involved in their synthesis. As a result of their complexity, traditional Edisonian, flask-based materials exploration techniques are unlikely to fully capture their full capabilities any time soon.

The autonomous fluidic robo-chemist adapted a two-stage synthesis of lead halide perovskite quantum dots through an initial synthesis of green-emitting nanomaterials followed by a sequential reaction to produce quantum dots with emission colors ranging from blue to red. The robotic fluidic reactors were designed and engineered in a way to enable reliable, continuous addition of quantum dot synthesis ingredients at any point during the multi-stage synthetic route. The AI-guided robo-chemist was then utilized to find the 8-parameter formulation of lead halide perovskite quantum dots for any desired emission color with minimum size polydispersity, and required only 40 min per material. The same formulation discovery task could take a highly trained chemist up to 5 months using current manual, trial-and-error techniques.

Through this work, Artificial Chemist 2.0 provides an all-in-one platform capable of self-guided learning, optimization, and on-demand manufacturing of emerging colloidal nanomaterials with multi-stage chemistries. The developed intelligent fluidic technology can be readily adapted for formulation development and manufacturing of materials beyond just lead halide perovskites.

Further development and adoption of autonomous robotic fluidic experimentation strategies will not only expedite the discovery of novel high-performing materials, but will enhance the scope of materials development through exploration of otherwise inconceivably large reaction spaces.

Reference: Abdel-Latif, K, et al., Self-Driven Multi-Step Quantum Dot Synthesis Enabled by Autonomous Robotic Experimentation in Flow, Advanced Intelligent Systems (2020). DOI: 10.1002/aisy.202000245