For a comprehensive use of solar cells a lot of research remains to be done. There are currently many research groups active in the field of photovoltaics in universities and research institutions around the world. For instance, the majority of polymer solar cells employ processing under high vacuum for one or more of the layers in the solar cell stack.

The highly conducting metal back electrode is applied by evaporation of the pure metal. It is not impossible to envisage mass production of polymer solar cells using vacuum processing, but it includes some drawbacks – in terms of processing speed, capital investment in processing equipment technical yield and direct process energy.

The highly conducting metal back electrode is applied by evaporation of the pure metal. It is not impossible to envisage mass production of polymer solar cells using vacuum processing, but it includes some drawbacks – in terms of processing speed, capital investment in processing equipment technical yield and direct process energy.

The important question to answer is which technique is most suited for manufacture of polymer solar cell modules with respect to technical yield, materials use and processing speed. In a recently appeared paper a group of four scientists from the Technical University of Denmark employed four different roll-to-roll (R2R) printing methods for printing silver back electrodes for polymer solar cell modules.

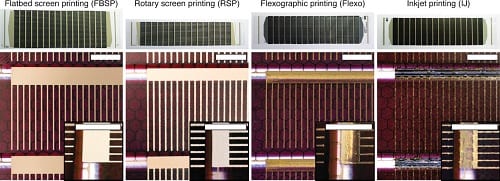

They applied flatbed screen printing, rotary screen printing, flexography, and inkjet printing. For these printing technologies, they compared applicability in large-scale production of serially connected polymer solar cell modules.

The Danish scientists analyzed advantages and disadvantages for each method and also outlined boundaries of their use and gave recommendations. They highlighted a few areas where development could lead to disruptive progress for the polymer solar cell as a technology.

The Danish scientists analyzed advantages and disadvantages for each method and also outlined boundaries of their use and gave recommendations. They highlighted a few areas where development could lead to disruptive progress for the polymer solar cell as a technology.

By way of example, they consider benign organic solvents still as possible solution whereas water-based inks present the ultimate goal in ink formulation. The development of new printable hole extraction layers that are compatible with the use of water based silver inks the four scientists regard as valiant subject for further development.

Featured Image: worradmu / FreeDigitalPhotos.net