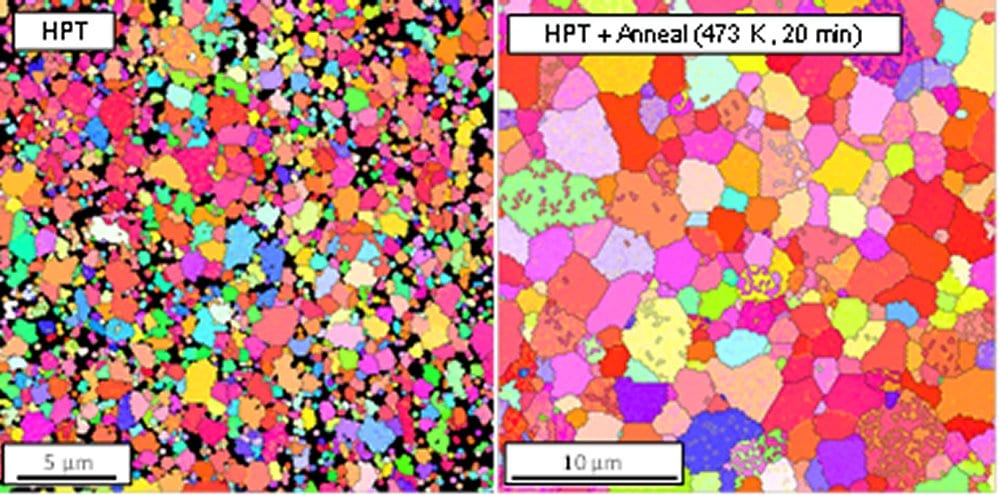

A new concept to solve the ductility problem of SPD-processed magnesium alloys was examined by using a ZK60 magnesium alloy processed by high-pressure torsion to obtain an HSHD material.

A new concept to solve the ductility problem of SPD-processed magnesium alloys was examined by using a ZK60 magnesium alloy processed by high-pressure torsion to obtain an HSHD material.

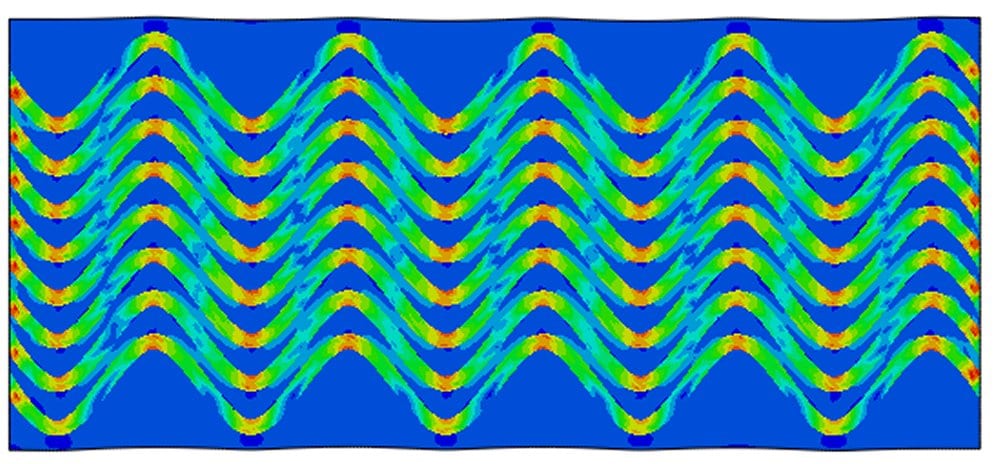

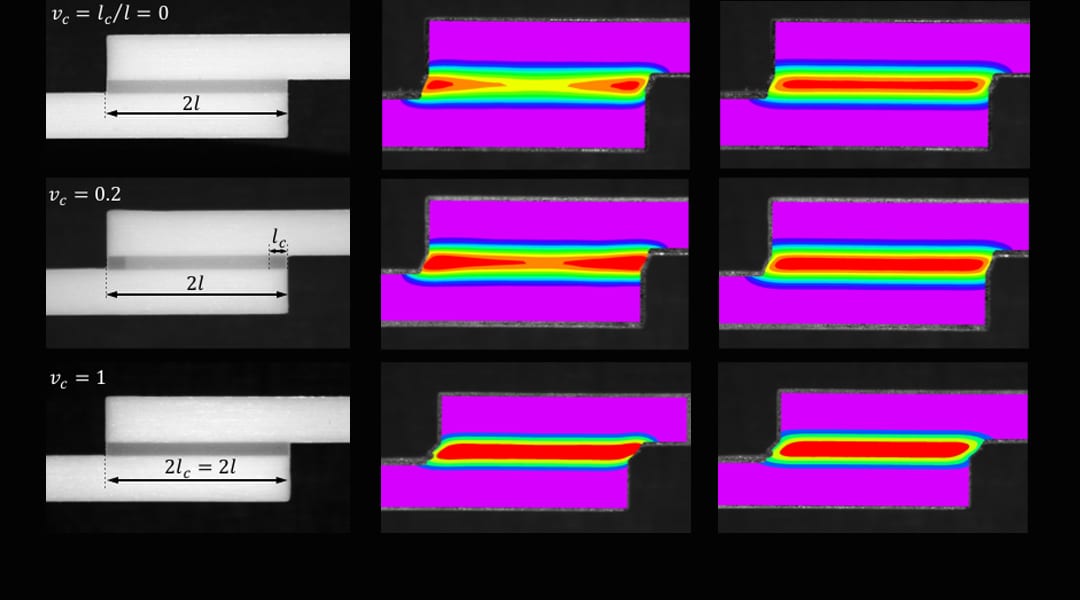

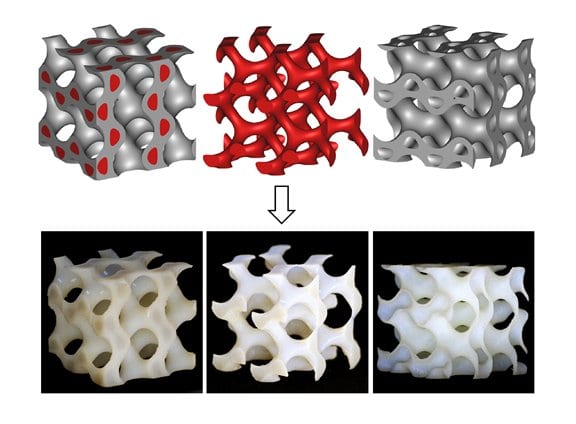

This work illustrates the importance and utility of considering the geometry and arrangement of the components of a composite material in addition to the properties of the component materials and shows how simply the design of the architecture can lead to accessing new desirable combinations of properties.

Significant implications of and recent progress made in iCVD-based technologies in three fields: electronic devices, surface engineering, and biomedical applications are discussed.

New designs were fabricated via multimaterial 3D printing and potential applications of sequential particle release mechanisms were systematically explored.

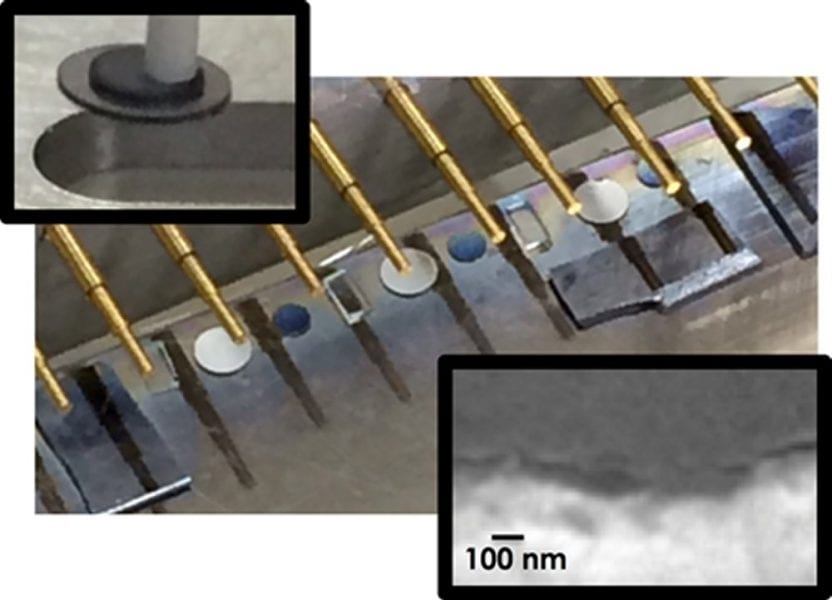

A simplified iCVD coater is developed that can be installed at low cost in most labs, and further use it to engineer submicron bond gaps in materials with common non-ideal features like curvature, roughness, and burrs.

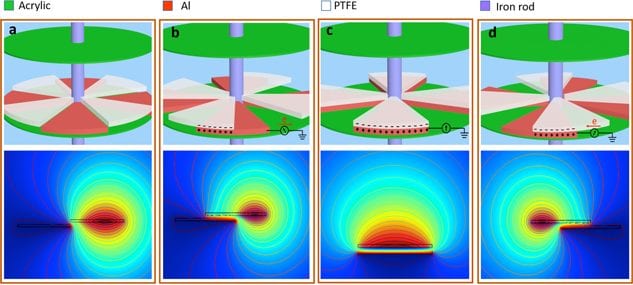

Two triboelectric nanogenerators with different configurations were designed and hybridized with Faraday electromagnetic induction generator to generate electricity, which can convert the kinetic energy from wind and flowing water and the electrostatic energy in water into electrical energy.

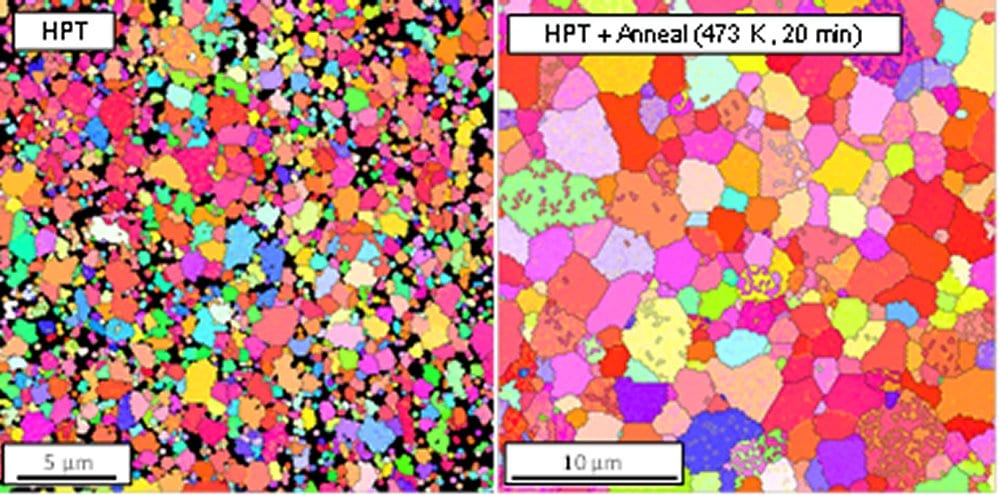

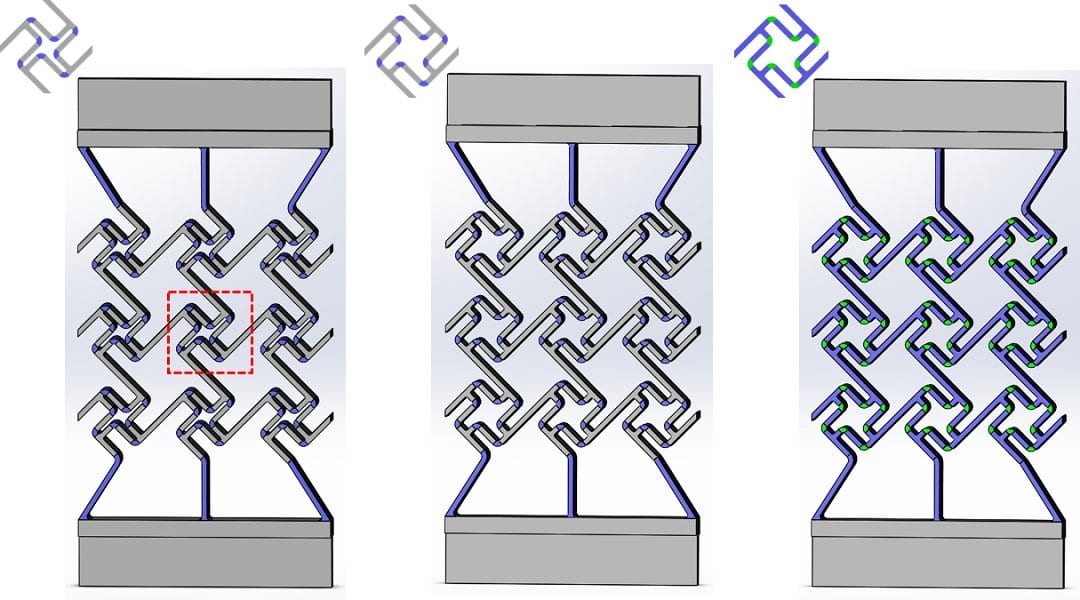

By crafting a spatially compliance-tailored bondlayer utilizing additive manufacturing, mechanical performance can be increased significantly, imparting greater strength, strain to break, and toughness, while maintaining stiffness of the homogeneous stiff bondlayer.

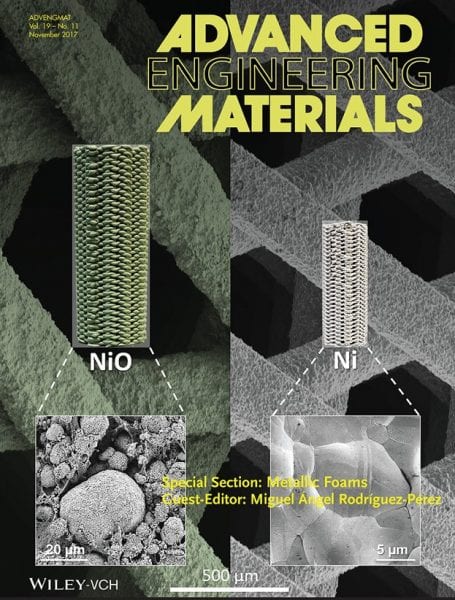

A special section of Advanced Engineering Materials features a selection of the papers presented during the 9th International Conference on Porous Metals and Metallic Foams (MetFoam 2015), which was held in Barcelona.

The use of Polyjet 3D printing technology to fabricate novel complex and architected lightweight cellular co-continuous composites has been proposed.

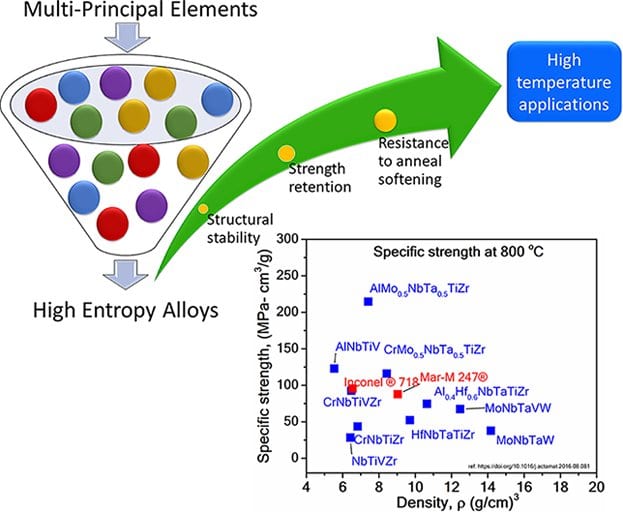

New work reviews advancements in the field of HEAs as a potential emerging material for high-temperature applications.