Recently B&R Industrial Automation unveiled a new intelligent transport system. As the Austria based company told, ACOPOStrak is the first system in the world to extend the economies of mass production down to batches of one. How do they want to achieve this ambitious goal?

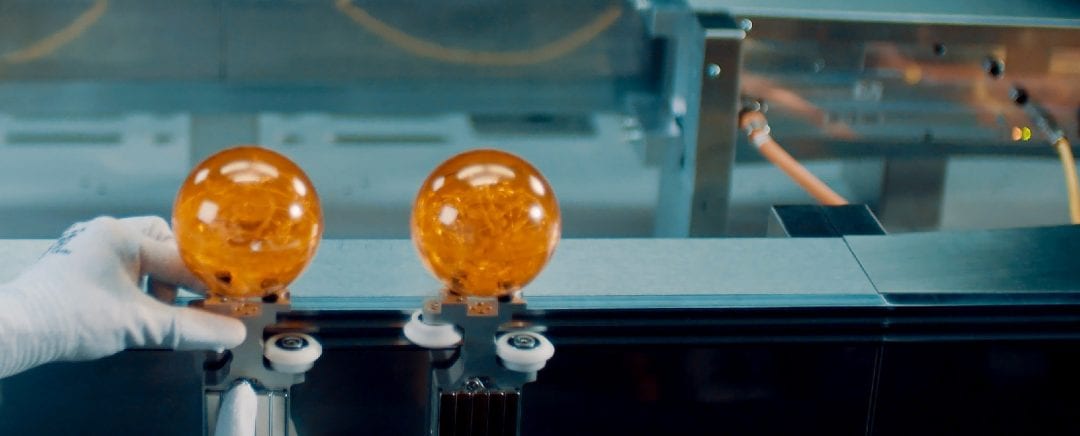

To switch products, the operator places the wheels of a new shuttle on the guides of the pit lane, while production continues at full speed on the rest of the track. Source: B&R

The purely electromagnetic diverters divide and merge product flows at full production speed. According to the company, among other advantages the novel transport system has the ability to include a pit lane in the track layout. New shuttles are mounted on the pit lane and then channeled onto the track’s actual production lines via a diverter. In the same way, any shuttles that are no longer needed can simply be rerouted to the pit lane. All of this takes place at full production speed. “It becomes possible to perform product changeover with zero downtime,” explained B&R’s mechatronics manager Robert Kickinger at the unveiling event.

ACOPOStrak’s design flexibility allows it to morph into all types of open and closed layouts by arranging different combinations of track segments. The system is capable of 5 g acceleration and reaches top speeds in excess of 4 meters per second with a minimum product pitch of only 50 millimeters. These performance numbers, together with the benefits of the diverters and the high design flexibility, form a total package like the market has never seen – as the companies‘ sales and marketing experts agree. We can get excited about the first customer feedback weather the new transport system passes daily production routine or not.