The wings of dragonflies and damselflies are composed of superlightweight, porous materials. As a fly emerges from water, CO2 gas in the wings is thought to maintain the pressure, keeping these structures intact. Synthesis of aerogels—the lightest solids known to man—could take inspiration from this ambient approach.

In their article in Advanced Materials, Dr. Xiao Han and Dr. Lidija Šiller from Newcastle University, UK, and their co-workers from Anbar University, Iraq; the University of Limerick, Ireland; the National Museum of Bosnia and Herzegovina; and Durham University, UK, report a new ambient drying method for aerogel fabrication.

Dr. Lidija Šiller: “The aerogel manufacture is currently limited by the drying process, because conventional drying methods from wet gel to aerogel require either a specifically pressurized chamber or expensive drying solvents.”

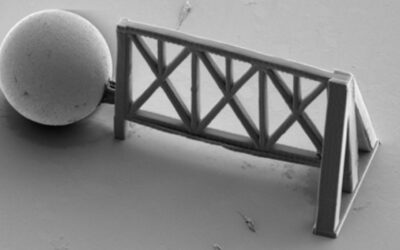

Dr. Xiao Han: “We were inspired by scanning electron microscopy of dragonfly wings, which shows aerogel structure and emergence of larvae of dragonflies out of the water. So, we designed a new chemical drying process to generate CO2 gas inside the wet gel by pushing liquid out of the wet gel.”

Trimethylchlorosilane (TMCS) was added to the wet gel containing a sodium bicarbonate solution, causing the production of CO2 gas. This gas becomes trapped in the aerogel pores, resisting pore collapse during drying and resulting in a monolithic aerogel.

Durable and freestanding layered silica aerogels were also made using this approach.

Dr. Lidija Šiller: “Our future work is toward manufacturing of various aerogel building products, which we believe will bring large energy savings to our society.”

To find out more about this ambient drying method for aerogels, please visit the Advanced Materials homepage.