The forces of time and nature can introduce small defects in materials. These defects have the potential to propagate, destroying the material completely. Graphitic carbon materials, similarly to metals, are vulnerable to the corroding power of oxygen. In the case of carbon nanotubes the protective strategy is very complicated and requires innovative solutions.

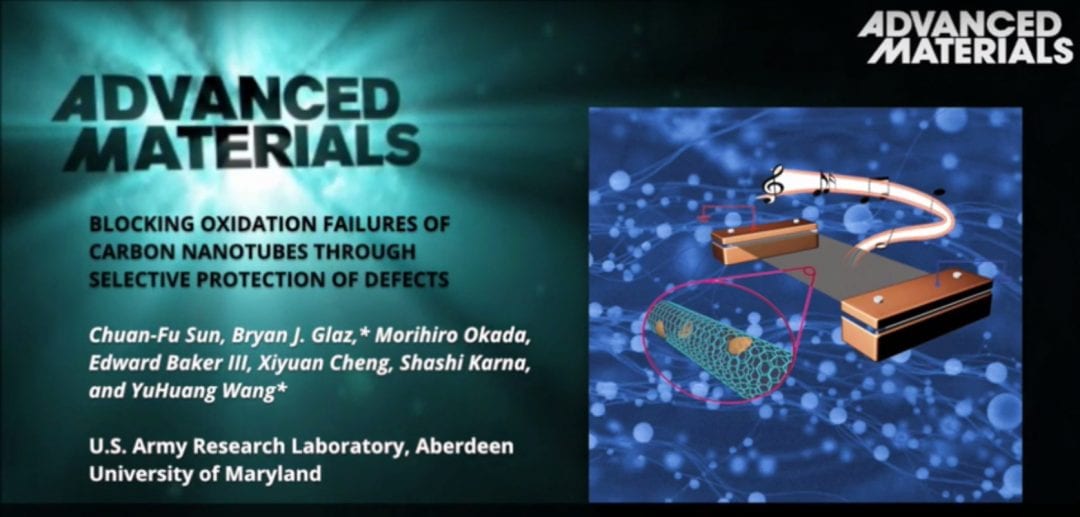

In a communication in Advanced Materials, Glaz from the U.S. Army Research Laboratory in Aberdeen, Maryland, and Wang from the University of Maryland, along with their co-workers, report how to selectively protect defects in carbon nanotubes from oxidation failure.

Heat-induced oxidation propagates from the defect sites. These are ‘patched-up’ with oxidation-resistant aluminum oxide.

Repeated atomic layer deposition of aluminum oxide filled the patches and formed a uniform coating for higher cycle numbers. The researchers tested their success by applying an electric current to carbon nanotube films. High-resolution infrared imaging showed that the breakdown propagates from a hotspot until complete failure.

As a result of the patching defects with 10 nm thin films of aluminum oxide, the breakdown occurs at much higher temperatures.

Furthermore, when applied in thermoacoustic devices, these defect-protected carbon nanotube films deliver a thermoacoustic output, which is 220% higher than from the unprotected species. The generated sound could reach an impressive 90.1 dB, which is not achievable with unprotected carbon nanotube films.

Prof. Wang: “So why is this important? This allows to block oxidation by patching only those defect sites and this makes it possible to create high power, thin-film thermoacoustic devices. In our work we’re focusing on carbon nanotubes, but this concept is generally extendable to other nanostructures, such as graphene.“

To know more, please go to Advanced Materials.