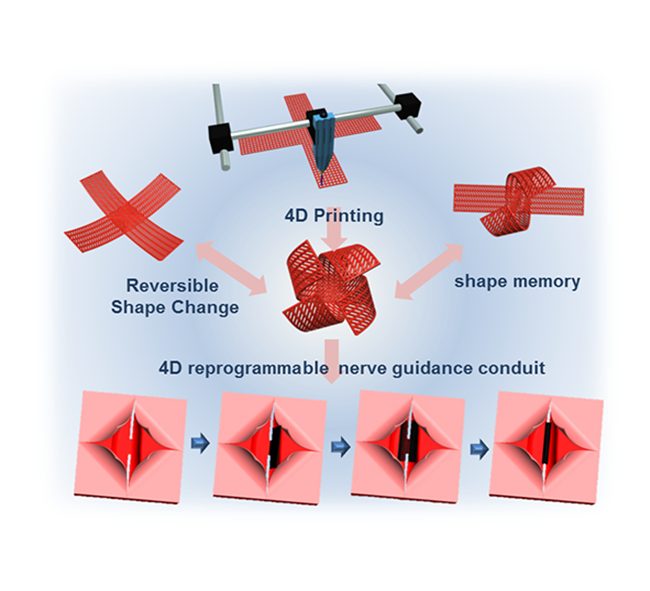

While 3D printing of organs and tissues becomes more and more established, 4D bioprinting will begin to come into play. The 4th dimension integrates time-dependent shape changes triggered, for example, by swelling or temperature changes. This offers the opportunity to realize more complicated folded structures in biomedical devices or soft robotics, as well as in tissue engineering to mimic dynamic changes of native tissues and organs.

Lijie Grace Zhang from George Washington University and colleagues present the stereolithographic 4D bioprinting of multiresponsive architectures for neural engineering.

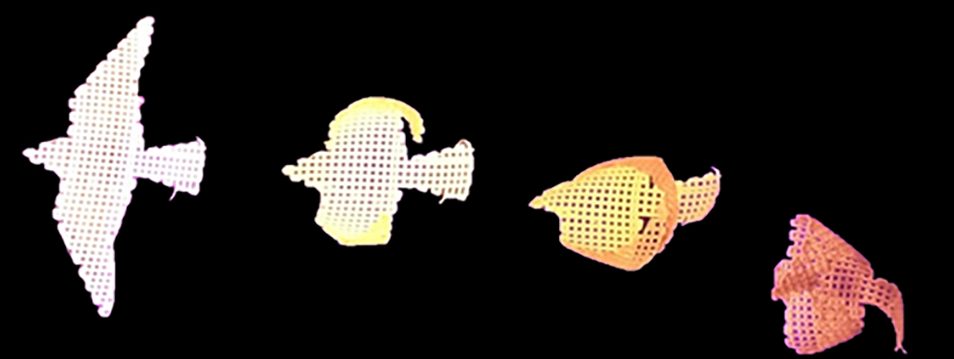

They used the naturally derived photocrosslinkable monomer SOEA (soybean oil epoxidized acrylate) as an ink. They were able to create a solidified flat star structure using UV crosslinked SOEA that could dynamically transformed into a claw structure, when washed with ethanol (see Figure).

They propose that laser‐induced graded internal stress, introduced through the printing process, is the major driving force of this 4D dynamic variation. Thereby, they could achieve a solvent-induced reversible shape change similar to a blooming and closing flower.

Furthermore, they incorporated various nanoparticles into the structures during the printing process to further enhance and modify the shape changing.

Nanohybrids including graphene could be used to generate structures resembling flying birds.

In a proof-of-concept study, they produced a smart nerve guidance conduit providing outstanding multifunctional characteristics for nerve regeneration, such as physical guidance, chemical cues, dynamic self‐entubulation, and seamless integration.