Soft morphing materials can adapt their structure and mechanical properties in response to their external environment. However, they are often limited by rigid mechanical parts that restrict complex geometries or have time-consuming custom-designed fabrication processes.

Alternatively, Professor Sung-Hoon Ahn and Min-Woo Han from Seoul National University have taken a bottom-up approach inspired by seamless soft morphing in biological systems. In Advanced Materials, they present a simple fabrication method for knitting smart fibres into complex soft morphing geometries, demonstrating functionality in beautiful knitted flowers.

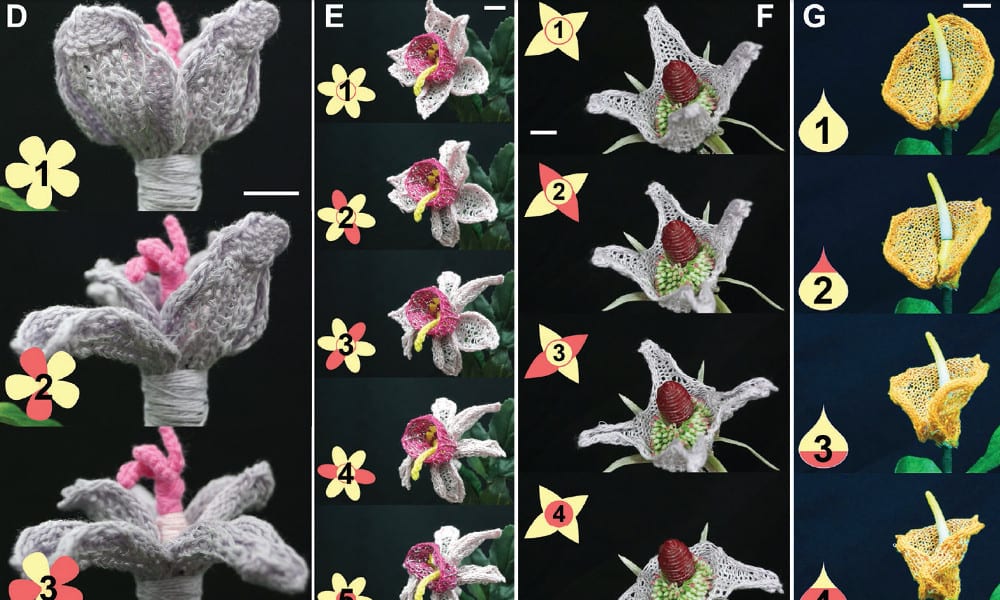

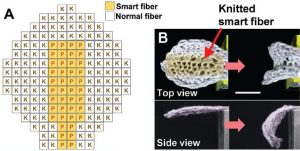

Thermally responsive fibers/shape memory alloys—polyester fibers wrapped around a thermally reactive smart material core—are knitted using four primary patterns. When a current is applied to the fibre it undergoes a phase change, which contracts the alloy length-wise and causes deformation of the knitted material. As a result, the morphable sections of the flowers (those made of smart fibers) deform and each petal can actuate by controlling the applied current (see figure). Furthermore, the flowers can be actuated without an applied current simply by blowing hot air (≈ 200°C) onto them.

Currently, these materials demonstrate one-way deformation and require manual assistance to return them to their original geometries; however, antagonistic knit patterns are a focus of future research, which will allow reversible actuation.