Have you ever tried to fix small pieces of a broken porcelain cup or plate? This task can be highly demanding, especially when the fracture surface is wet or even contaminated, for example by dirt or fat. It will only succeed if special adhesives are used that are able to adhere in a moist environment or, even better, in which the cross-linking reaction is catalyzed by water molecules. The same problem appears for fixing small bone fragments caused by trauma within the human body by using bone-glues. Here, further crucial prerequisites for successful adhesives are not only the absence of cytotoxicity of the adhesive components, but also sustained adhesion during the healing period while supporting bone tissue regeneration. This continued adhesion in wet conditions is particularly challenging.

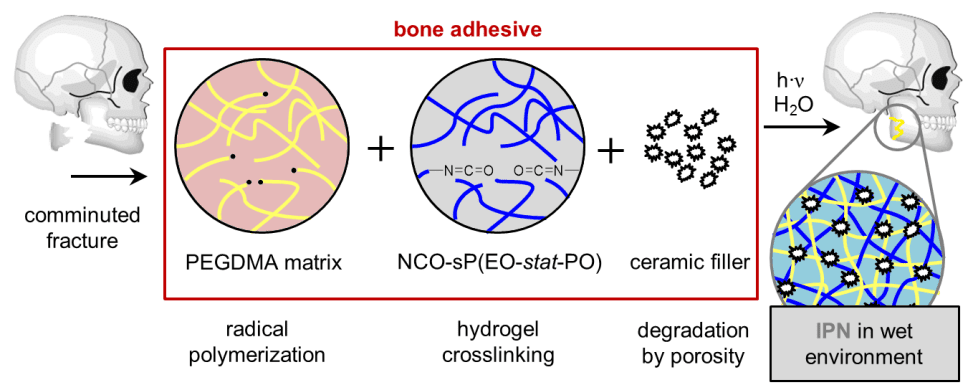

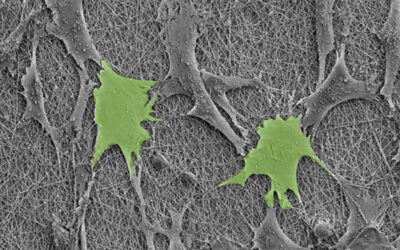

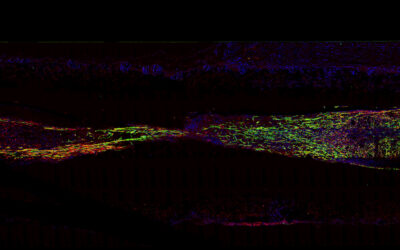

Based on these demands, Groll, Gbureck and co-workers designed a new material strategy that shows a significantly improved wet adhesion of bone adhesives. To achieve this, they transferred isocyanate chemistry known from technical applications to possess wet-adhesive properties to bone glues by using a six armed star shaped polymer that bears isocyanate groups at the distal endings of the polymer chains. When these molecules are used as an additive to a PEG-dimethacrylate matrix, an interpenetrating network (IPN) structure is rapidly formed by polymerization and polyaddition reactions. This rapid local fixation of the isocyanate groups leads to cytocompatible curing, better than radical polymerization with TEMED, and to a network that exhibits significantly improved bone−adhesive shear strength. Also, inorganic fillers can be supplemented into the formulation that may act as porogens. The study in Advanced Healthcare Materials demonstrates in vitro cytocompatibility as well as applicability of the system under clinical conditions.