Over the course of the last 10 years, research in the field of triboelectric nanogenerators (TENGs) has rapidly increased in pace. These devices can readily convert mechanical into electrical energy, and as a consequence the potential applications of these devices are broad, ranging from chemical sensing to communication aids. However, their fragility has prevented these systems from being used in harsh environments.

An international team recently reported the development of a novel, hardy TENG that fits on a car’s brake pads. This TENG can be used to convert the some of the mechanical energy involved in car braking to electrical energy. In order to withstand the high temperatures on the surface of the brake, the design of this TENG was carefully optimized.

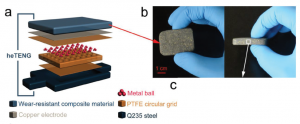

TENG brake schematic.

The optimized TENG is shown to the left. The outside layer is a composite material designed to withstand high temperature. Inside this layer is a copper electrode, and then a plastic layer that surrounds a cavity. This hollow contains a number of tiny aluminum balls. When the device vibrates due to the friction of braking, the balls bounce off the plastic casing, causing a build-up of charge. This charge build-up can then be harnessed as electric current.

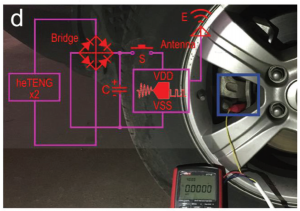

The team tested a number of different materials and established that the optimum number of aluminum balls to include in the cavity was ten. With an optimized device in hand they show that it can withstand temperatures of between –30 and 550 °C. The TENG was installed in a car (see below) and was found to be able to harvest electric current.

The electrical output from these brakes might be useful for powering electronic elements within the car. However, the team initially focused on using the output from the TENG to act directly as a sensor. They showed that the signal could give real time information about whether the brakes needed to be replaced, what the tire pressure was, and the load variations for each of the wheels.

This interesting new device could perhaps find use as an early warning system for various safety parameters in smart cars. The authors hope, more generally, that this demonstration of TENGs operating in harsh environments may broaden the horizon for TENG applications research.

TENG (shown in the blue box) installed on a brake pad.