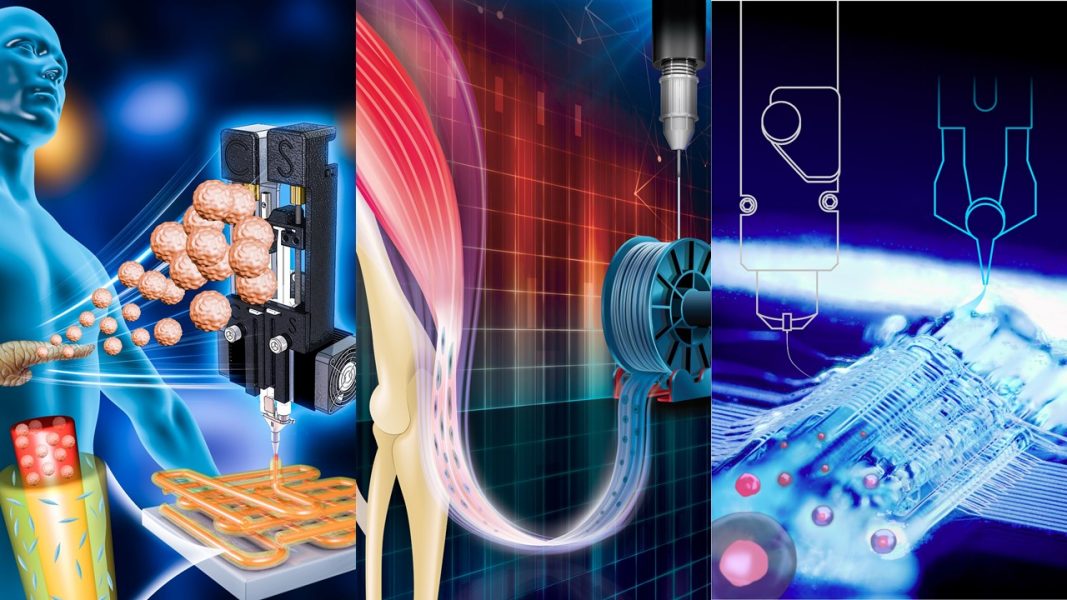

Certainly, 3D printing is one of the fastest moving topics in biomaterials research. Biofabrication ultimately aims at building tissue models for regenerative medicine purposes.

The Advanced Healthcare Materials Special Issue on “Building Blocks for Biofabricated Models” (edited by Jos Malda and Jürgen Groll) showcases several new developments in this exciting research area.

The issue features a number of new developments of bioinks:

Sang Jin Lee et al. (Wake Forest Institute for Regenerative Medicine) present a novel photo‐crosslinkable kidney‐specific extracellular matrix (ECM)‐based bioink formulation that can support human kidney cell maturation and tissue formation in a printed construct. “Fiber Reinforced Cartilage ECM Functionalized Bioinks for Functional Cartilage Tissue Engineering” is described by Daniel J. Kelley (Trinity College Dublin). To further advance melt electrowriting (MEW), Jürgen Groll et al. (University of Würzburg) present a strategy for the “Permanent Hydrophilization and Generic Bioactivation of Melt Electrowritten Scaffolds,” where a photo‐leucine is covalently immobilized, that enables the binding of sterically demanding molecules on demand.

Two further MEW studies are also included:

Paul D. Dalton, Torsten Bunk and coworkers (University of Würzburg) report on the “Generation of Sheet‐Like Tissue Constructs from Multicellular Spheroids.” They show this using adipose‐derived stromal cells, which display adipogenic differentiation when they are placed into box‐structured pores of MEW scaffolds. Miguel Castilho, Jos Malda, and coworkers (Utrecht University), also use MEW and combine it with extrusion‐based bioprinting for “Simultaneous Micropatterning of Fibrous Meshes and Bioinks for the Fabrication of Living Tissue Constructs.”

The issue covers also a number of different tissues:

Kidney and cartilage, as already described above; printing bone is highlighted in a review by Ali Khademhosseini, Nureddin Ashammakhi, and their coworkers(UCLA), which is also covered in an article by Michael Gelinsky and Anja Lode (TU Dresden), who “3D Plotted Biphasic Bone Scaffolds for Growth Factor Delivery.” “Bioreactors for Cardiac Tissue Engineering” are also reviewed by Ali Khademhosseini, Roberto Parra‐Saldivar (Monterrey, Mexico) and coworkers. Furthermore, Tendon Tissue Engineering is covered by Wojciech Swieszkowski et al. (Warsaw University of Technology), while Lawrence J. Bonassar et al. (Cornell University) “Engineer the Meniscus‐to‐Bone Insertion.” Printing skin is featured by an article from Dong‐Woo Cho et al. (POSTECH) on a “Perfusable Vascularized Human Skin Equivalent Composed of Epidermis, Dermis, and Hypodermis“. The replacement of whole rat tracheas using “Scaffold‐Free Structures of Human Cells Using a Bio‐3D Printing System” is published by Takeshi Nagayasu et al. (Nagasaki, Japan).

Finally, two articles deal with printing of pancreatic islet cells: Zhilian Yue, Patrick T. Coates, Gordon G. Wallace, and coworkers (University of Wollongong), develop a “Coaxial 3D Printing Platform for Biofabrication of Implantable Islet‐Containing Constructs,” while Michael Gelinsky et al. (TU Dresden) focus on “3D Bioprinting of Functional Islets of Langerhans in an Alginate/Methylcellulose Hydrogel Blend.”