Scientists have taken inspiration from one of the oldest natural materials to exploit the extraordinary qualities of graphene, a material set to revolutionise fields from computers and batteries to composite materials.

Published today in Nature Communications, a Monash University study led by Professor Dan Li has established, for the first time, an effective way of forming graphene, which normally exists in very thin layers, into useful three-dimensional forms by mirroring the structure of cork.

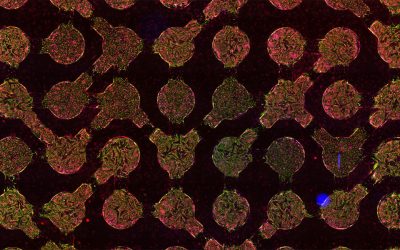

Graphene is formed when graphite is broken down into layers one atom thick. In this form, it is very strong, chemically stable and an excellent conductor of electricity. It has a wide range of potential applications, from batteries that are able to recharge in a matter of seconds, to biological tissue scaffolds for use in organ transplant and even regeneration.

Professor Li, from the Department of Materials Engineering, said previous research had focused mainly on the intrinsic properties and applications of the individual sheets, while his team tackled the challenge of engineering the sheets into macroscopically-useable 3D structures.

“When the atomic graphene sheets are assembled together to form 3D structures, they normally end up with porous monoliths that are brittle and perform poorly,” Professor Li said.

“It was generally thought to be highly unlikely that graphene could be engineered into a form that was elastic, which means it recovers well from stress or pressure.”

The researchers used cork, which is lightweight yet strong, as a model to overcome this challenge.

PhD student, Ling Qiu, also from the Department of Materials Engineering, said modern techniques have allowed scientists to analyse the structure of such materials and replicate nature’s efficient design.

“The fibres in cork cell walls are closely packed to maximise strength and individual cells connect in a honeycomb structure which makes the material very elastic,” Mr Qiu said.

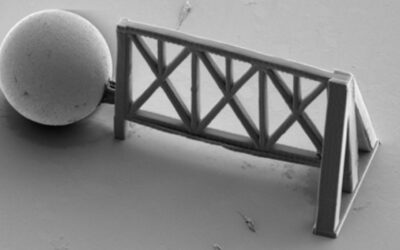

Using a method called freeze casting, the researchers were able to form chemically modified graphene into a 3D structure that mimicked cork. The graphene blocks produced were lighter than air, able to support over 50,000 times their own weight, good conductors of electricity and highly elastic – able to recover from over 80 per cent deformation.

“We’ve been able to effectively preserve the extraordinary qualities of graphene in an elastic 3D form, which paves the way for investigations of new uses of graphene – from aerospace to tissue engineering,” Professor Li said.

“Mimicking the structure of cork has made possible what was thought to be impossible.”

Source: Monash University