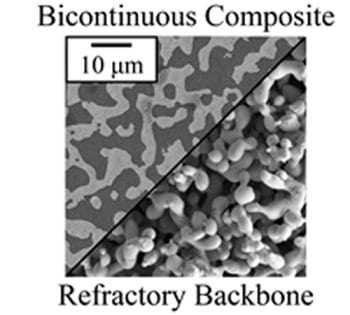

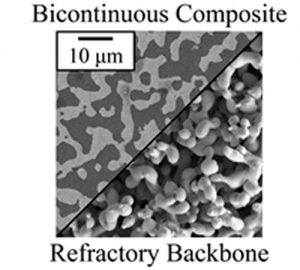

In their latest research Jonah Erlebacher et al. use a new metallurgical processing technique, liquid metal dealloying (LMD), to fabricate the first bicontinuous metal-metal microcomposite. There is a well-defined concept in metallic materials that smaller microstructural features yield stronger materials, and extensive mechanical testing has been used to study size effects on the mechanical properties of metal microstructures. However, there has been a challenge in assembling nano- and microscale objects into a bulk material without creating defects and weak points in the structure. LMD solves this challenge because it is a self-organization process that works from the bottom up. The particular materials we studied here were made of Ta and Cu, and are comprised of two interpenetrating phases with a tunable length scale that showed a significant increase in strength with decreasing feature size.

In their latest research Jonah Erlebacher et al. use a new metallurgical processing technique, liquid metal dealloying (LMD), to fabricate the first bicontinuous metal-metal microcomposite. There is a well-defined concept in metallic materials that smaller microstructural features yield stronger materials, and extensive mechanical testing has been used to study size effects on the mechanical properties of metal microstructures. However, there has been a challenge in assembling nano- and microscale objects into a bulk material without creating defects and weak points in the structure. LMD solves this challenge because it is a self-organization process that works from the bottom up. The particular materials we studied here were made of Ta and Cu, and are comprised of two interpenetrating phases with a tunable length scale that showed a significant increase in strength with decreasing feature size.

Using LMD the team were are able to fabricate ~1 cm3 of nanocomposite material in a matter of minutes with length scales as small as 50 nm and as large as 10 mm. The LMD process is simply controlled liquid metal corrosion. The researchers say their system was chosen for the following properties: Ti and Ta form a homogenous alloy across all composition ranges, Ta is immiscible with Cu, and molten Cu has a high Ti solubility. During LMD, they immersed a parent alloy of TiTa into a bath of molten Cu. The molten Cu selectively dissolves Ti out of the alloy while allowing Ta to diffuse along the metal/liquid interface and reorganize into a porous network. Copper remains in the pores and fills the dealloyed phase volume as it penetrates into the parent alloy. After full penetration, a dense bicontinuous composite with a characteristic ligament diameter is formed upon cooling. This system is general and can be extended to any refractory element X (e.g., W, Mo, Nb, V) that alloys well with titanium and is immiscible with Cu.

The group believe that this is a new class of materials and that their work points the way to improvements in the mechanical properties of metals through the design of bulk three-dimensional bicontinuous nancomposites. These materials will likely find many applications in structural applications that require high strength, ductility, and high density of internal interfaces.