Since the advance of micro-/nanoelectronics, the urgency to develop reliable, versatile and ultimately high-throughput surface stamping techniques for micro-/nanocontact printing has rapidly increased.

Classical stamp-based printing consists in the use of solid elastomeric stamps for transferring molecules from the (liquid) ink to the substrate to be patterned. Using elastomeric stamps has the intrinsic advantages of a conformal stamp-substrate adhesion and optimal contact formation that in turns lead to molecule transferring onto the target surface with minimal loss.

Although classical nanoprinting is a high-throughput method for the modification of large area substrates, it features some specific drawbacks that are intrinsically related to the use of solid, nonrefillable stamps. In particular, only the molecules that are adsorbed on the stamp outer surface can be transferred to the substrate. This leads to a series of cascade effects that limit the application of classical nanoprinting techniques: i) the range of materials that can be printed is limited, as an optimal trade-off between adhesion to the stamp and adhesion to the substrate must be enabled, ii) molecule loading and unloading often require that nanoprinting is carried out under controlled atmospheric conditions in order to prevent fast ink evaporation, iii) the number of stamping cycles that can be performed before reloading the stamp with the ink is also limited.

In this context, capillary nanostamping has emerged as a more versatile fabrication technique for nanocontact printing, and the work of Prof. Steinhart and co-workers published in Advanced Functional Materials is a representative case.

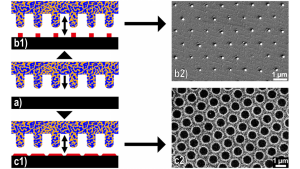

Figure. a) Mesoporous silica stamp (blue), soaked with ink (orange) approaching the target substrate (black). b1) Stamping of C60(red)/toluene solutions on perfluorinated glass slides, b2) SEM image of arrays of c60 dots by capillary nanostamping on perfluorinated glass. c1) Stamping of 1-dodecanethiol(red)/ethanol solutions on gold-coated substrate, c2) SEM image acquired with in-lens detector of arrays of 1-dodecanethiol dots by capillary nanostamping on gold-coated substrate.

Capillary nanostamping with silica stamps penetrated by spongy continuous mesopores is here reported. Due to the morphology of the stamps, the ink can be either continuously or discontinuously supplied to the stamp/substrate contact surface during stamp operation. Even more, the mesopores can be used as internal ink reservoir, that is, capillary nanostamping can be repeated multiple times without the need to refill the mesoporous stamps with the ink and, remarkably, with no detrimental effects on the quality of the stamped pattern. Besides, capillary nanostamping can be carried out under ambient conditions, and allows for the transfer of larger amounts of ink to the target substrates.

Prof. Steinhart and his group has reported two limiting cases of capillary nanostamping using two different model inks: i) solutions of fullerene C60 in toluene that were stamped onto perfluorinated glass slides, and ii) ethanolic 1-dodecanethiol solutions stamped onto gold-coated surfaces.

Fullerene C60 has a higher affinity to itself than to the target substrate. Thus, liquid ink bridges form between the contact elements of the mesoporous stamps and the glass slide, while toluene spreading is thermodynamically prevented (Figure b1). During the contact time, C60 enriches within the liquid bridges and crystallizes into nanoparticles that are eventually smaller than the stamp/substrate contact area (Figure b2).

By contrast, 1-dodecanethiol has a larger affinity to the gold substrate surface than to itself. In this case, despite ethanol spreading on the gold-coated substrate, arrays of submicron 1-dodecanethiol dots were obtained that are larger than the contact elements (Figure c1,2). Possible explanations for this include a counteraction between the pressure drop across the concave menisci that the ink forms on the stamp surface at the mesopore openings and the van der Waals forces between the ink and the gold surface, and/or a reduced wettability of the 1-dodecanethiol dots induced by ethanol.

Regardless of the nanoprinting mechanism, the chemical heterogeneity of such Au nanopatterned surfaces could also enable templated dewetting of polystyrene (PS) melts, eventually yielding ordered arrays of discrete PS nanoparticles on gold-coated substrate.

Beyond the reported examples, the authors anticipate that capillary nanostamping has the potential to enable the deposition of arrays of micro-/nanometer drops of a broad range of inks on a diverse range of substrates. Potential applications of the technique may thus include the production of sensor arrays, e.g. for bioanalytics, and of topographically or chemically patterned surfaces with tailored wettability and adhesive properties.