Olivine-structured LiFePO4 has attracted much attention as a promising cathode material for lithium ion batteries for electric vehicle (EV) applications. However, its poor conductivity limited its practical applications until the introduction of carbon coating. Since then, significant progress has been made in understanding and controlling phase purity, particle size and carbon coating of the C/LiFePO4 composite material.

Olivine-structured LiFePO4 has attracted much attention as a promising cathode material for lithium ion batteries for electric vehicle (EV) applications. However, its poor conductivity limited its practical applications until the introduction of carbon coating. Since then, significant progress has been made in understanding and controlling phase purity, particle size and carbon coating of the C/LiFePO4 composite material.

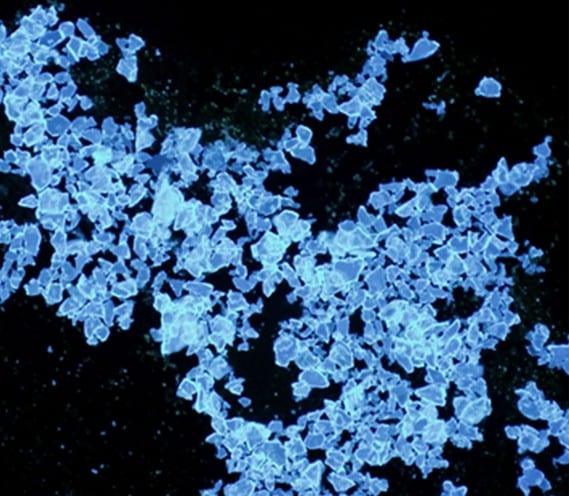

While the carbon coating is a critical component in C/LiFePO4 composites, however, little attention has been paid to alternative nanocarbon coatings, especially the interaction of nanocarbon coatings on LiFePO4. This is partly because there is no appropriate model material or effective nano-characterization tools for this study. Prof. Xueliang (Andy) Sun and colleagues from Western University in Canada, cooperating with Phostech Lithium Inc., have now managed to overcome this problem using a molten technique to achieve an ingot sample with a large flat surface, which allows them to directly study the LiFePO4 carbon coating.

For first time, this work provides a local visualization study on carbon coating, particularly the influence of impurity phases. By combining focused ion beam lithography (FIB), High-resolution transmission electron microscopy (HRTEM), and micro-Raman mapping techniques, the team intensively investigated and identified the interaction between carbon and LiFePO4 as well as the nature and effects of impurity phases on carbon coating for LiFePO4. During carbon coating process, the phosphorus-rich phase is found to have an inhibiting effect (or no positive catalytic effect) on carbon formation while iron-rich phases (mainly iron phosphides) promote carbon growth by contributing to more carbon deposition and higher graphitic carbon content.

These findings provide an important guideline for the improvement of carbon coating quality in C-LiFePO4 composite material. Furthermore, this methodology will help us to understand and reveal the basic carbon-deposition process and structure on LiFePO4, leading to further improved performance of this promising electrode material.