An innovative concept in the fiber-reinforced thermosets sector has been introduced by SGL Group. It is a complete material tool box consisting of pre-impregnated semi-finished products based on the new “Snap-Cure” epoxy resin. This E420 epoxy resin system combines fast curing times (less/equal 3 minutes at greater/equal 150°C) with good storage stability (4 weeks at room temperature).

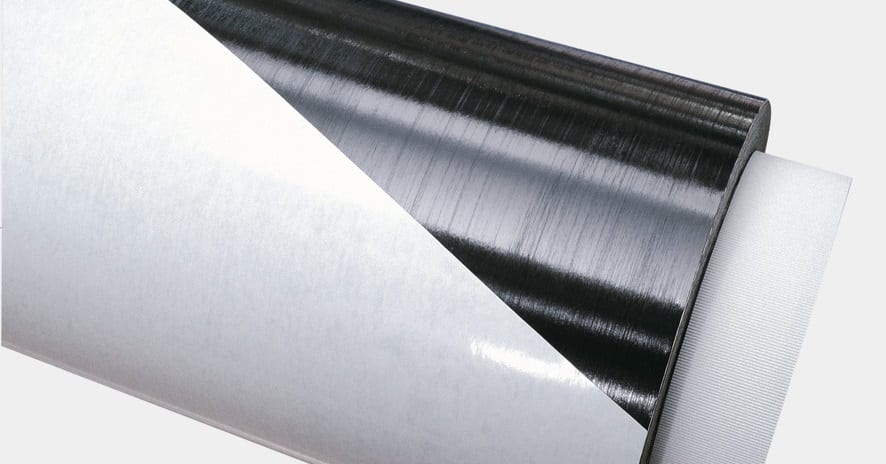

The pre-impregnated semi-finished products also have optimized tack for automated processing, as told by the German based company. The high glass transition temperature of 140–150°C enables the component to be demolded at high temperatures. These materials are supplied on the basis of SIGRAFIL 50k carbon fibers and as glass fiber-reinforced semi-finished products.

“The various materials in our new material tool box can be flexibly combined and processed, so offering maximum design freedom to users. At the same time, they reduce the complexity involved in the qualification and production of components. This is because they are based on the same resin system, enabling a high degree of standardization to be achieved and ensuring excellent compatibility between the different semi-finished products,” explained Stefan Geh, Head of Product Groups at SGL Group, describing the advantages of the new material tool box.

According to SGL’s pledges, users only have to go once through the costly and time-consuming qualification process for the matrix system (e.g. adhesive compatibility, EDC suitability) but then have a very diverse range of semi-finished products at their disposal. New lightweight design concepts exploiting the particular advantages of individual semi-finished products help satisfy the requirements for cost-efficient, sustainable large-scale manufacture of CRP components in the automotive industry.