Researchers use hot water and pressure to circumvent the need to use toxic chemicals in the production of organic plastics.

Researchers use hot water and pressure to circumvent the need to use toxic chemicals in the production of organic plastics.

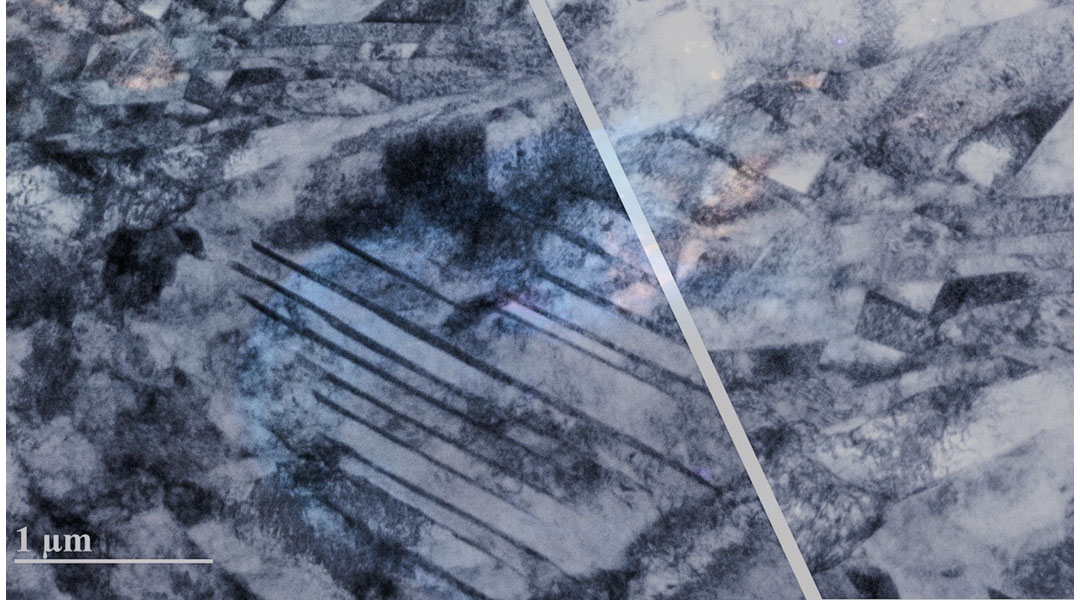

Novel graphene‐reinforced elastomeric isolators are a viable, low‐cost alternative to reinforce buildings against earthquake damage.

The combination of ionic liquids with polymers allows the development of smart materials with superior properties and tailored functionalities for several areas of application.

Researchers report a fast and efficient titanium alloy processing technique that requires up to 50% less heat.

A new route to synthesize plastics not only moves away from fossil fuels but enhances the likelihood of recycling.

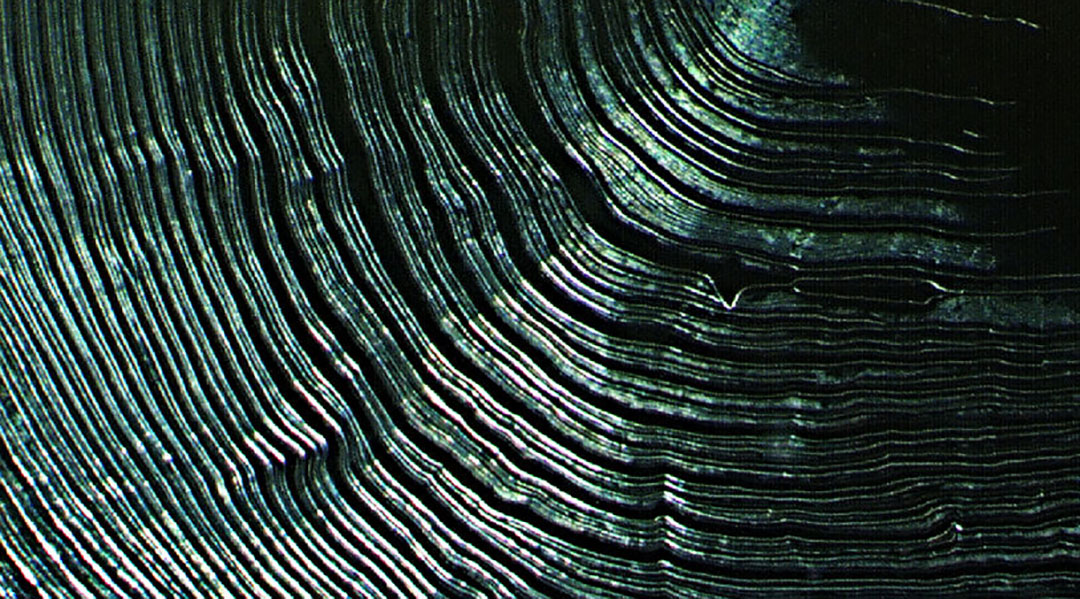

Researchers fabricate a highly selective ZIF‐8 gas separation membrane.

Today’s green chemistry technologies open the route to a broader and richer economy for lemons, well beyond the fresh fruit and fruit juice markets.

Researchers create new “superglue” with two simple ingredients: plant-based cellulose nanocrystals and water.

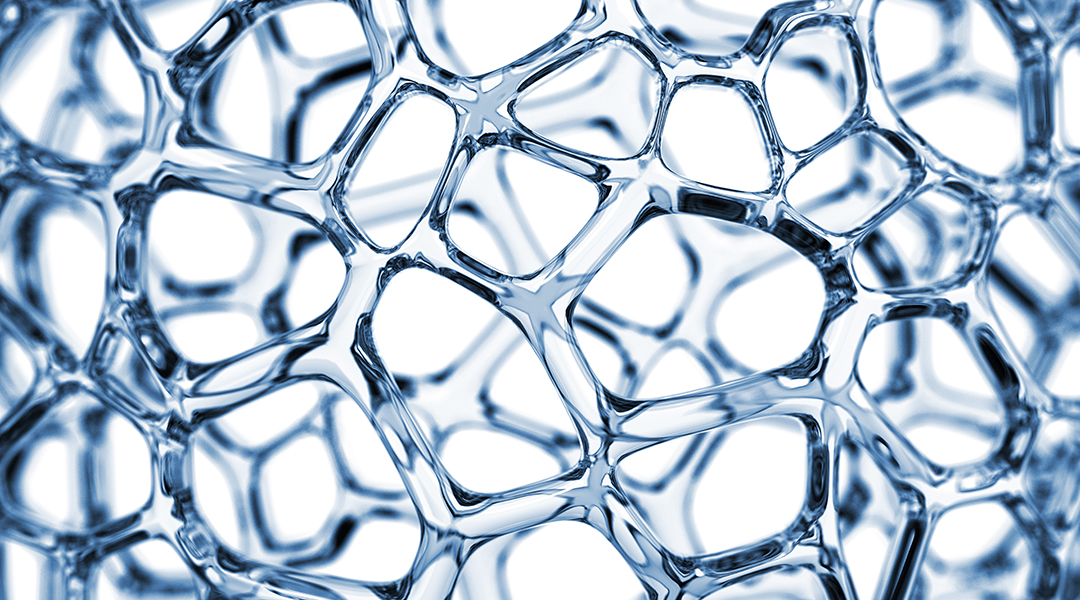

Researchers design a porous 3D graphene lubricant composite for harsh conditions and high loads.

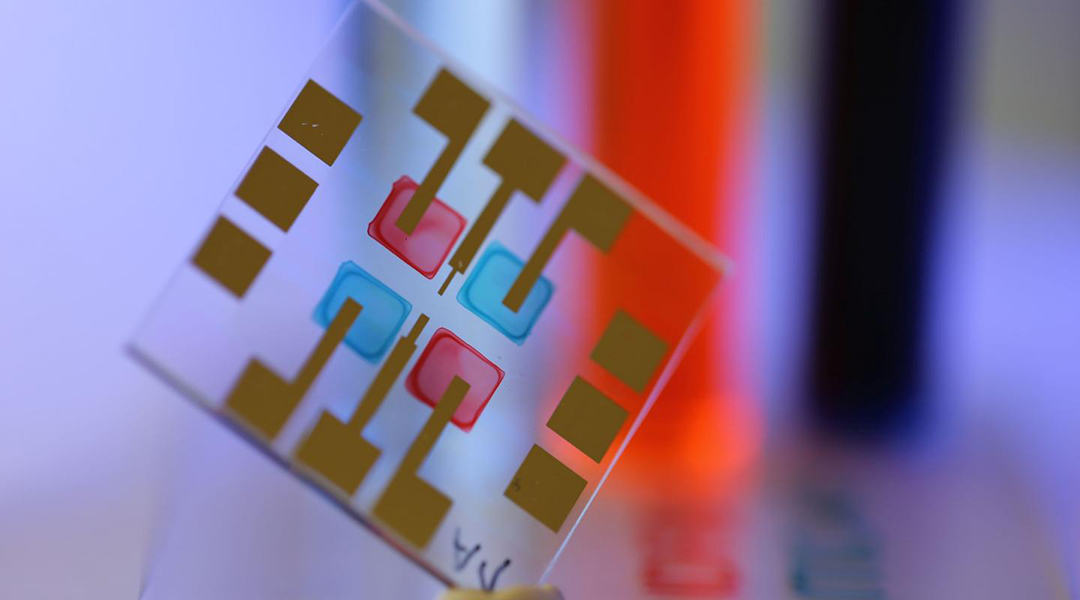

Color-selective organic light sensors are produced by inkjet printing with semiconducting inks.