For centuries, silk farmers reigned supreme, their coveted threads gleaned from silkworms, making them the envy of the ancient world. In modern times, spider silk has become a material to envy due to its amazing physical properties — a remarkable blend of strength and flexibility.

Unfortunately, replicating large scale spider silk production resembling historical silkworm farms isn’t likely to happen anytime soon. “I don’t think mass production of spider silk is realistic,” explained Fei Sun, a researcher at the Hong Kong University of Science and Technology. “I think scalability is still a big issue.”

According to him, rearing spiders on farms is unrealistic due to spiders’ aggressive and cannibalistic nature. However, advances in synthetic biology are allowing researchers like Sun to adapt spider silk for biomedical uses that don’t require large scale production.

In a paper published in Advanced Functional Materials, Sun and colleagues describe a new method for producing spider silk proteins in bacteria. Their process is not only efficient, but it also allows them to equip the threads with a variety of different molecules, that enhance the spider silks natural attributes or even interact with living tissues.

A web of new techniques

To create “customizable spider silk”, the team wove together two genetic and chemical technologies. The first is recombinant DNA, a synthetic biology technique that allows researchers to isolate and manipulate specific genes and even combine them with the genome of another species.

With this technique, Sun could add spider silk genes into the bacteria, Escherichia coli, transforming the bacterial cells into spider silk protein factories.

Next, the team employed a relatively new method from the field of synthetic chemistry called genetically encoded click chemistry. In short, this is a technique for efficiently connecting (or “clicking” together) protein molecules like Lego building blocks.

The team used this method to genetically add a tag onto the spider silk protein, which serves as an attachment point for other molecules of interest that are labelled with a corresponding catcher molecule. This transforms normal spider silk into a scaffold that can be coated with all types of useful molecules.

Functional threads

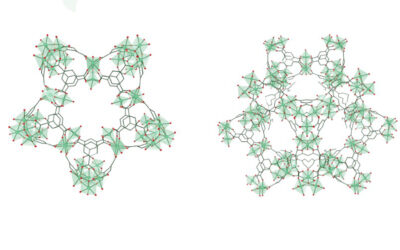

In two separate experiments, the team was able to show the power of this new technology. First, they coated the spider silk threads with an enzyme called silicatein. This enzyme is used by marine sponges to transform silicic acid into silica, a glass-like structure the sponges use in their bodies.

The result was an organic-inorganic hybrid of spider silk proteins coated in the glass-like silica. This not only proved the team could modify the silk proteins, but according to Sun, “We may be able to convert this into an optical fiber.”

To demonstrate the silk proteins potential for biomedical uses, the team next coated the spider silk proteins with molecules known as cell binding ligands. As the name suggests, these molecules attach to the surfaces of cells and are used for a variety of purposes in the body such as wound healing and tissue growth.

Spider silk proteins coated with one of two different ligands were used as platforms for cell culture, and after 10 days of growth, the ligand-coated silks were covered with more cells than uncoated silk. Not only that, the cells on the ligand coated silks grew in a more elongated way, resembling how actual cells in tissues like the vascular system grow and function, showing that these silk scaffolds could be used for wound healing or regrowing tissues.

Endless possibilities

According to Sun, this is a promising proof of concept. The spider silk proteins are already desirable due to their strength, small size, and ability to resist degradation by the body’s enzymes and proteins. Furthermore, several reports claim that the silks do not provoke the immune system.

Now, with a way efficiently producing silks and transforming them into customizable scaffolds, Sun believes the potential uses are only limited by the types of molecules they can attach to the silks. Thankfully, advanced AI is also available for this as well, Sun said.

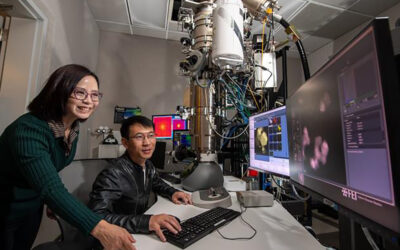

Powerful AI programs like AlphaFold that predict how molecules and proteins will fold, function, and attach lets Sun visualize how a desired protein will behave on the silks and how best to place it. Now, rather than making a guess and running experiments to see if it works, they can think about the desired outcome and then see which proteins might work for any given scenario.

Sun and his collaborators are now investigating specific uses for the functionalized silk proteins such as a platform for regrowing neurons or growing organoids. For Sun, these advances are driven by our ability to look to nature for inspiration and solutions.

“Researchers want to harness biological systems to produce materials, which can be comparable, or even exceed what our ancestors have been doing for 1000s of years,” he said.

Reference: Angela Ruohao Wu, Fei Sun, et al. Designed Multifunctional Spider Silk Enabled by Genetically Encoded Click Chemistry, Advanced Functional Materials (2023) DOI: 10.1002/adfm.202304143

Feature image credit: Nathan Dumlao on Unsplash