A graphene sheet can be incorporated with poly(ε-carprolactone) (PCL) to enhance the mechanical and thermal properties of shape memory polyurethane (SMP) if the filler can be properly dispersed through the polymer. Writing in the Journal of Polymer Science: Polymer Physics, Jae Whan Cho and colleagues introduce an effective technique using click coupled graphene to obtain high-performance nanocomposites.

A graphene sheet can be incorporated with poly(ε-carprolactone) (PCL) to enhance the mechanical and thermal properties of shape memory polyurethane (SMP) if the filler can be properly dispersed through the polymer. Writing in the Journal of Polymer Science: Polymer Physics, Jae Whan Cho and colleagues introduce an effective technique using click coupled graphene to obtain high-performance nanocomposites.

Graphene holds great potential in applications like molecular electronics, field emission devices, actuators, and sensors. “Click coupling is an emerging modification method for graphene’s functionalization due to its high specificity, quantitative yield, compatibility with a variety of functional groups, and versatile applications under mild conditions,” says Cho. “The controlled high performance of graphene-based polymer nanocomposites, including the mechanical, electrical, and thermal applications, can be created by using click chemistry.”

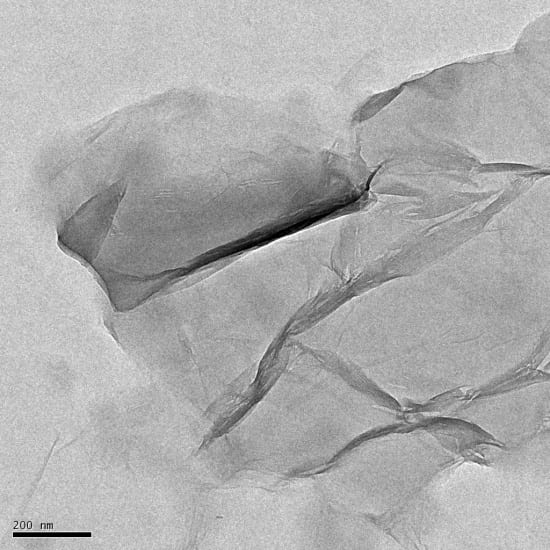

The use of the click coupling approach allows a high grafting ratio of PCL to a single graphene sheet, resulting in good solubility and processability. As a result of the successful grafting, the modified surface characteristics allow for a homogenous dispersion of functionalized graphene in the SMP matrix displaying a strong reinforcement effect.

The breaking stress, elongation-at-break, and Young’s modulus of the SMP were greatly enhanced, increasing by 109%, 28%, and 158% respectively for 2.0 wt% of the PCL-GS nanofiller compared to pure SMP. Moreover, the thermal stability, thermal conductivity, and shape recovery behavior of the host polymer were also unprecedentedly improved after the insertion of the click coupled graphene sheet.

“This approach offers complementary advantages, such as the grafting of high molecular weight polymer chains and a better coverage ratio on the graphene surface. This is also though to greatly extend the application range of graphene and encourage the growth of graphene based high performance nanocomposites for shape memory application, actuator, sensor, and etc,” explains Cho.

Looking to expand the approach, Cho says that click chemistry is useful for modifying the surface properties of other carbon nanomaterials such as carbon nanotubes, graphene, and fullerene to satisfy special needs. “This methodology will help us to develop more advanced biomaterials, nanostructured polymers, and hybrids based on carbon nanomaterials.”