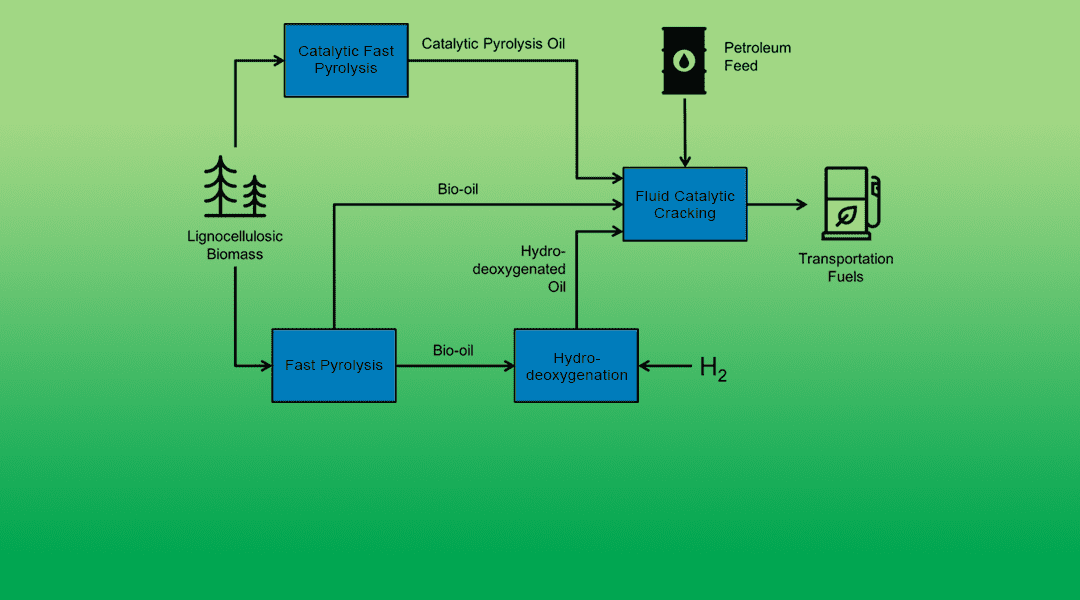

Lignocellulosic biomass, i.e. non-edible dry plant matter such as wood, crop residues and energy crops, is an abundant and renewable energy source. Utilization of biomass for the production of second generation biofuels can facilitate the reduction of CO2 emissions from the transportation sector, reduce the dependency on petroleum-derived fuels and help establish a secure energy supply. Lignocellulosic biomass can be converted directly to liquid fuels via fast pyrolysis or catalytic fast pyrolysis. The liquid product from fast pyrolysis is known as bio-oil and is a low-quality fuel that has higher energy density and can be transported more efficiently than solid biomass. On the other hand, the liquid product from catalytic fast pyrolysis is known as Catalytic Pyrolysis Oil (CPO) and is a higher quality fuel with improved energy value and stability compared to bio-oil. Alternatively, bio-oil’s energy value and stability can be improved via partial hydro-deoxygenation to produce Hydro-Deoxygenated Oil (HDO).

The biomass-derived oils described above contain oxygen and their properties differ significantly from conventional petroleum-derived fuels. Therefore, further processing is necessary to obtain transportation fuels. Co-processing bio-oil or CPO or HDO with petroleum streams in conventional refineries is a cost-effective way to facilitate the commercialization of second generation biofuels by utilizing already-existing refinery infrastructure. Among the refinery processes, Fluid Catalytic Cracking (FCC) can readily adjust to changes in feed composition and is therefore the most suitable process for the introduction of biomass-derived oils in the refinery.

An advanced review recently published in WIREs Energy and Environment showed that significant research has been carried out up to date on the FCC co-processing of biomass-derived oils. Bio-oil has been the most challenging to co-process, mainly due to its unstable nature, which caused significant operating problems for many research groups. However, these initial hurdles have been overcome and demonstration-scale tests have exhibited that the technology is ready for commercialization, provided some modifications in the FCC unit are employed in order to overcome problems with bio-oil immiscibility and charring. On the other hand, research on CPO and HDO has showcased that these oils are a lot easier to co-process than bio-oil and that more renewable carbon can be transferred to the liquid hydrocarbon product of the FCC process when these oils are used. However, HDO and CPO co-processing technology is currently less mature, as the majority of studies with these oils have been carried out at the lab-scale, with only a couple of studies having been conducted at pilot-scale so far.

Co-processing biomass-derived oils results in a liquid hydrocarbon product with increased aromatic content that contains only a very small amount of biomass oxygenates. Hydrogen donation reactions from the petroleum feed act synergistically to facilitate the conversion of the unstable and reactive biomass oxygenates into liquid hydrocarbons, although overall, co-processing results in slightly increased solid byproduct yields from the FCC unit. These changes in product composition and product yields from the FCC unit are expected to be small because biomass-derived oils are blended in very low amounts, about 3-5 wt.%. Therefore, the co-processing of biomass-derived oils is not expected to disrupt the normal operation of the refinery and is a very promising and cost-effective way to bring second generation biofuels to the market.

Kindly contributed by Stylianos Stefanidis.