Liquid crystals have emerged as a prominent material for creating the next generation of advanced optical devices due to their high sensitivity to external fields and tunable properties.

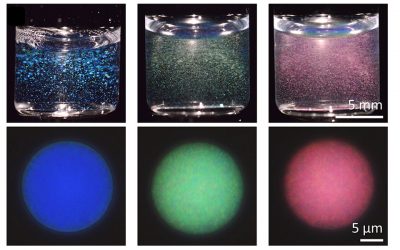

In Advanced Functional Materials, Prof. Jan Lagerwall from the University of Luxembourg and his colleagues present a facile, reproducible, and scalable procedure to prepare uniformly colored cholesteric liquid-crystal rubber films, which could translate to commercial production.

The films were produced through a simple evaporation of solvent from the cholesteric liquid-crystal rubber precursor, producing thin, millimeter-thick cholesteric liquid crystal rubber.

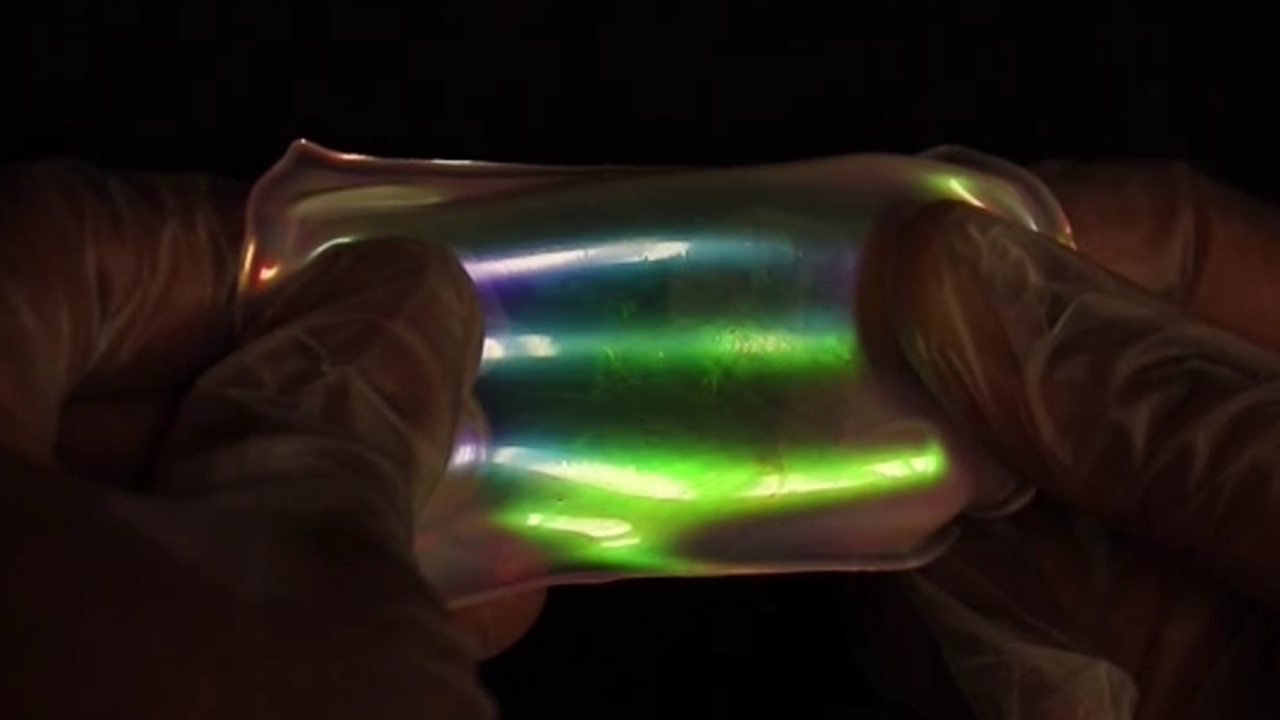

“If a cholesteric liquid crystal is polymerized into an elastomer, a very interesting material arises that combines the striking optical properties of cholesterics with the elasticity of a rubber,” said Dr. Rijeesh Kizhakidathazhath, the paper’s lead author.

“The cholesteric helix gets coupled to the elastomer, which means any mechanical deformation changes the optical properties. For example, when you stretch the film, the reflected color changes from red to blue.”

Using their technique, the team was able to produce large-area cholesteric liquid crystal elastomers (CLCEs) with uniform reflection color that is tunable across the full visible spectrum through stretching or compressing.

The resultant film shows a dramatic blue shift while stretching it uni‐or biaxially orthogonal to the helical axis, and it immediately relaxes when the strain is removed, fully recovering the original state, even if the film was kept under strain for more than a day.

“We believe this simple mix‐and‐pour approach to fabricate high‐quality autonomous tensile or pressure sensors, which can easily be scaled up, can have a significant impact on the potential for commercial applications of CLCEs,” Prof. Lagerwall concluded.

To find out more about CLCEs and their production, please visit the Advanced Functional Materials homepage.