Worldwide, a lot of effort is being devoted to developing devices based on biocompatible materials. Biocompatibility plays a key role, particularly in applications where humans are in contact with materials such as medical applications.

As non-toxic and water-soluble bio-polymers, cellulose and its derivatives represent a sustainable alternative to plastics, and these materials have already made their way into various applications.

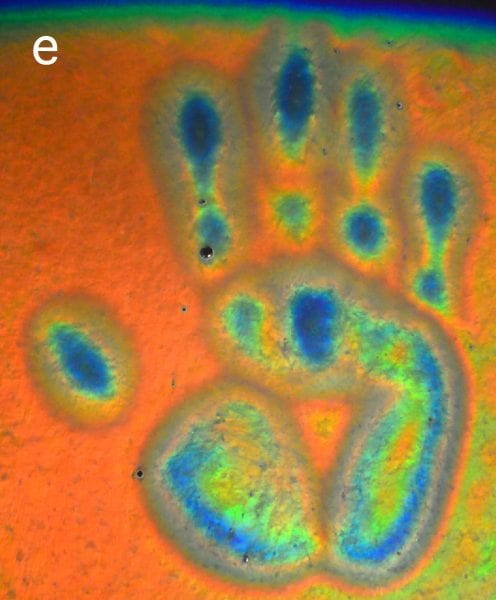

In their recent study published in Advanced Optical Materials, Silvia Vignolini (University of Cambridge) and co-workers make use of hydroxypropyl cellulose (HPC) to develop optical strain sensors. The material can form a cholesteric liquid crystalline phase, thereby permitting a Bragg-like reflection of circularly polarized light at specific wavelengths. The active component of the sensor consists only of HPC and water, and is sandwiched between polymer sheets – resulting in a flexible device. When applying strain, a change in the pitch of the cholesteric structure of the bio-polymer induces a change of color.

In their recent study published in Advanced Optical Materials, Silvia Vignolini (University of Cambridge) and co-workers make use of hydroxypropyl cellulose (HPC) to develop optical strain sensors. The material can form a cholesteric liquid crystalline phase, thereby permitting a Bragg-like reflection of circularly polarized light at specific wavelengths. The active component of the sensor consists only of HPC and water, and is sandwiched between polymer sheets – resulting in a flexible device. When applying strain, a change in the pitch of the cholesteric structure of the bio-polymer induces a change of color.

Special features of these sensors include environmental friendliness, easy scalability, durability for more than six months and a reversible response to strain. What makes the sensor even more attractive is that different deformation modes such as compression, shear, and extension can be differentiated. The colorful hand print in the image proves that with these kind of sensors even large and complex pattern can be registered.

Vignolini and her colleagues back up the experimental results with theoretical modelling, thus making the story complete and giving an insight into the mechanism involved.

The authors envision that their sensors can be used for biomedical and biomechanical applications, for example minimally invasive surgery or motion detection. To learn more about these biocompatible optical strain sensors please find the full article here.