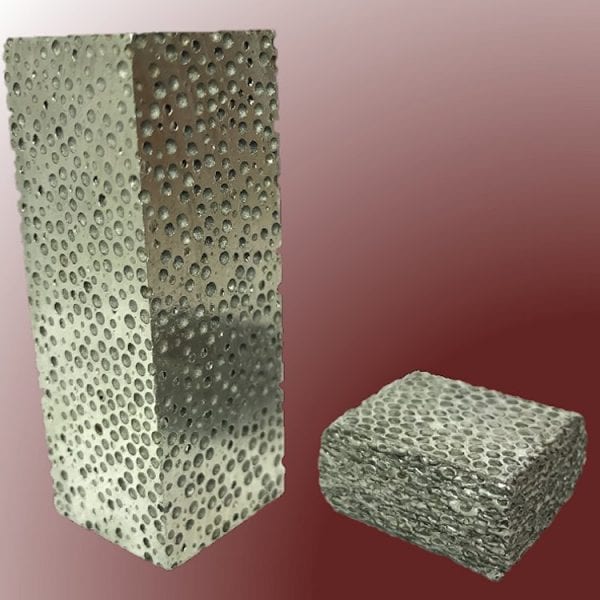

Composite metal foam (CMF) is a lightweight material made by hollow metal spheres stacked tightly together creating dispersed porosities, that are completely surrounded by a bulk metallic body. CMF has a unique set of properties and has found many uses in multiple engineering fields. The spheres within the material allow it to act like a kitchen sponge when pressed, without rebounding to its original shape when the pressure is removed.

Composite metal foam (CMF) is a lightweight material made by hollow metal spheres stacked tightly together creating dispersed porosities, that are completely surrounded by a bulk metallic body. CMF has a unique set of properties and has found many uses in multiple engineering fields. The spheres within the material allow it to act like a kitchen sponge when pressed, without rebounding to its original shape when the pressure is removed.

When used under pressure, the collapse of the spheres within composite metal foam provides the ability to absorb the impact energy of cars, trains, and helicopters during an accident. This useful property of CMF allows it to better protect the operators and passengers inside these vehicles; a concept very similar to the performance of Styrofoam carrying eggs or bubble wrap protecting fragile items during transportation, but much stronger. When added to structures and safety systems, CMF can reduce the overall weight, without sacrificing the performance. In addition to vehicle safety systems, composite metal foam has also found use in ballistic armors, radiation shielding, and insulation against fires, making it an innovative choice to improve current safeguards.

A new Review highlights the background and evolution of composite metal foam from its inception until now, and compiles an understanding of how its properties are tailored to specific applications in a wide range of fields, from space exploration to driving your car to work, as it continues to be developed and optimized for a wide array of uses.