Fabricating electronic devices with increasingly smaller components requires ever more powerful methods. One approach is optical lithography, which uses light (often with a 193 nm wavelength) to transfer geometric patterns to substrates. Optical lithography, however, suffers from scaling limitations that make the preparation of small-scale (~22 nm) features problematic. A different approach, that retains the existing 193 nm technology, is the directed self-assembly of block copolymers.

The successful application of the method very much depends on the ability to produce materials with defect densities of <0.01 defects per square centimeter, making a fundamental understanding of how and why defects occur critically important. Reporting in the Journal of Applied Polymer Science Glenn Fredrickson and co-workers at the University of California, Santa Barbara use self-consistent field theory (SCFT) to gain insight into the thermodynamic and kinetic factors influencing defect formation in diblock copolymers. “We are excited that our latest generation of simulation tools based on SCFT are providing valuable insight into process and formulation variables that dictate directed self-assembly patterns, defects, and placement error”, says Frederickson.

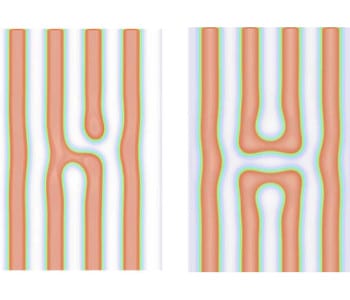

The team focuses on two commonly observed defects that occur in cylinder-forming AB diblock copolymers that are laterally confined in narrow trenches. The first defect examined is dislocation, a linear misalignment of polymer chains in a lattice. The second is disclination, a linear defect relating to polymer chain bending. The study analyzes the rates, energetic barriers, and kinetic pathways associated with removing these metastable defects by annealing. Furthermore, conditions favoring minimal defect formation are proposed.

They also investigate the energetics and kinetics at work in the transition from defective to perfect states during the melting process. Here, they apply the string method, which finds the local minimum energy paths separating local energetic minima in a free energy landscape. A major finding is the prediction that the annealing out of defects in cylinder-forming block copolymers should be significantly faster than lamellar-forming symmetric block copolymers (seconds vs. minutes or hours). The defect density of <0.01 defects per square centimeter is a target defined by the International Technology Roadmap for Semiconductors, and as the team concludes, the “findings should provide useful guidelines for the design of optimized patterning processes with low defect concentrations”.

In the future, the group’s work will move “beyond templated line and space patterns towards understanding fundamentals and design rules associated with contact multiplication in directed self-assembly.”