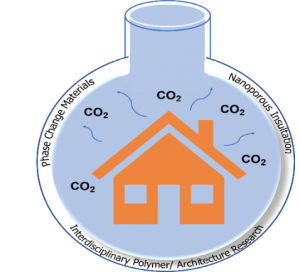

Slowing the effects of climate change by reducing greenhouse gases is a pressing goal of the global scientific community. The building sector contributes a large percentage of total global CO2 emissions, which are generated in the construction of building materials as well as from fossil fuels used to heat and cool homes. Therefore, maximizing the energy efficiency of homes should be at the forefront of the agenda to reduce CO2 emissions.

In an attempt to address this issue, zero-energy and passive housing concepts have emerged. Although these homes are highly energy-efficient, the energy-inefficient homes already in existence cannot be easily modified to include the same energy-saving features. Replacing insulation materials with those having lower thermal conductivity, such as nanoporous foams, is one practical way to enhance energy efficiency. Installing automated temperature control systems is another route, where phase change materials (PCMs) have great potential.

In an attempt to address this issue, zero-energy and passive housing concepts have emerged. Although these homes are highly energy-efficient, the energy-inefficient homes already in existence cannot be easily modified to include the same energy-saving features. Replacing insulation materials with those having lower thermal conductivity, such as nanoporous foams, is one practical way to enhance energy efficiency. Installing automated temperature control systems is another route, where phase change materials (PCMs) have great potential.

Timothy E. Long and Katherine V. Heifferon from Virginia Tech review the polymer properties that govern nanoporous foams and PCMs for energy-efficient housing.

They state that two factors must be controlled in manufacturing nanoporous foams that have the desired features of low density and small pore size: CO2 solubility and glass transition temperature. Synthesizing low-cost, novel polymers with these properties is essential for their commercialization as insulation materials with low thermal conductivity, but they must face competition with aerogels and vacuum insulation panels (VIPs).

PCMs, on the other hand, rely on encapsulation technologies that efficiently increase surface area to absorb heat and withstand volume changes. Solid–solid PCMs are promising in this regard, but their energy adsorption ability must be improved if they are to replace current technologies.